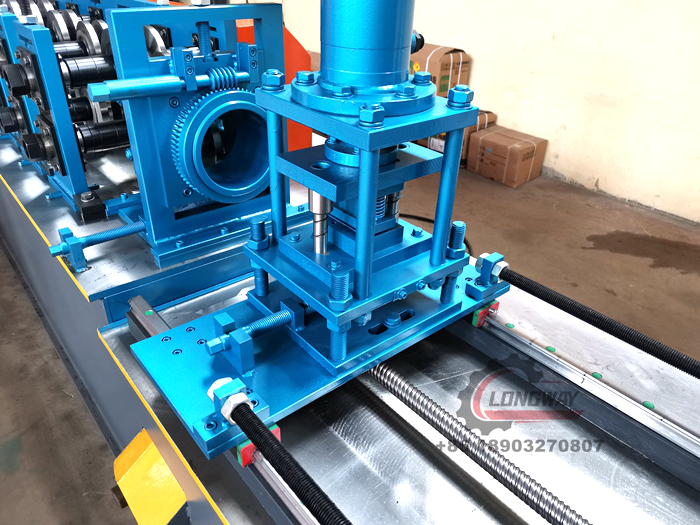

custom ridge cap machine

Custom Ridge Cap Machine The Future of Roofing Technology

In the world of roofing, efficiency, precision, and customization are crucial. As roofing projects become more complex and clients demand more tailored solutions, the need for specialized equipment has emerged. Enter the custom ridge cap machine—an innovative piece of technology designed to meet the dynamic demands of the roofing industry.

Ridge caps are the finishing touches on a roof, providing not only aesthetic appeal but also crucial protection against the elements. They seal the ridge line, preventing water penetration and safeguarding the structure beneath. Traditionally, installing these caps required a labor-intensive process, often resulting in inconsistencies in quality and finish. However, with the advent of custom ridge cap machines, roofing contractors can now produce ridge caps that are not only uniform but also tailored to their specific project requirements.

These machines come with a variety of features that make them indispensable tools for roofing professionals. First and foremost, customization is at the heart of their design. Users can adjust dimensions, profiles, and even colors to match specific project specifications. This level of customization allows contractors to cater to unique architectural designs, ensuring that the roofing materials complement the overall aesthetic of the building.

Moreover, the efficiency of these machines dramatically improves production times. Traditional methods required time-consuming manual labor for cutting and shaping materials. In contrast, a custom ridge cap machine automates these processes, allowing for rapid production of ridge caps without compromising on quality. This not only speeds up project timelines but also reduces labor costs, making it a financially sound investment for roofing companies.

custom ridge cap machine

Another significant advantage of these machines is their versatility. They can work with a variety of materials, including metal, asphalt, and synthetic composites. This flexibility allows contractors to diversify their offerings, providing clients with more options tailored to their needs. Whether it’s a residential roofing project or a large commercial installation, the custom ridge cap machine can handle it all.

In addition to boosting efficiency and customization, using a custom ridge cap machine can also enhance the overall quality of the roofing installation. With precise manufacturing, ridge caps fit seamlessly onto the roof, reducing the chances of leaks or other issues over time. This built-in quality assurance is vital for contractors who want to build a reputation for excellence in their work.

Environmental considerations are also increasingly important in the construction industry. Custom ridge cap machines can contribute to sustainability efforts by minimizing waste during production. The precision cuts and custom dimensions mean fewer leftover materials and less impact on the environment.

In conclusion, as the roofing industry continues to evolve, the introduction of custom ridge cap machines is a game-changer. They provide roofing contractors with the tools needed to produce high-quality, customized solutions efficiently. With their numerous advantages, these machines are not just an investment in technology; they are an investment in the future of roofing. As more professionals adopt this innovative equipment, we can expect to see enhanced quality, reduced costs, and a significant shift in how roofing projects are approached and executed.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025