Custom Designed Tile Roll Forming Machine for Glazed Tiles Production and Manufacturing Solutions

Custom Glazed Tile Roll Forming Machine Revolutionizing Tile Production

In today’s fast-evolving construction industry, efficiency, quality, and customization are paramount. To meet these demands, the introduction of advanced machinery has proven to be a game-changer, particularly in the production of glazed tiles. Among these machines, the custom glazed tile roll forming machine stands out for its ability to produce tiles that are not only aesthetically pleasing but also structurally sound and durable.

The Significance of Glazed Tiles

Glazed tiles are widely used in both residential and commercial construction due to their numerous benefits. They offer exceptional durability, resistance to water, and ease of maintenance. The glossy finish of glazed tiles adds an element of elegance and sophistication to spaces, making them a preferred choice for flooring, walls, and decorative elements. Additionally, glazed tiles come in a variety of colors and designs, allowing for personalization and creativity in architectural design.

How Custom Glazed Tile Roll Forming Machines Work

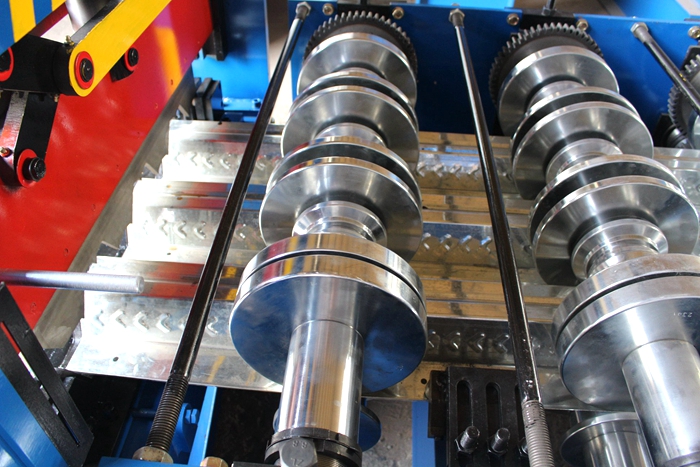

Custom glazed tile roll forming machines utilize a process known as cold forming, which is efficient and versatile. The process begins with raw materials that are fed into the machine, where they are shaped and molded using a series of rollers. These machines are designed to produce tiles with uniform thickness and accurate dimensions, ensuring high-quality output.

The customization aspect is one of the most significant advantages of these machines. Manufacturers can adjust the machine settings to create tiles of various sizes, shapes, and finishes according to specific client requirements. This flexibility allows for a vast range of designs, from traditional to contemporary styles. Moreover, manufacturers can integrate different glazing techniques, resulting in unique textures and colors that cater to diverse market demands.

Benefits of Using Custom Glazed Tile Roll Forming Machines

custom glazed tile roll forming machine

1. Efficiency and Speed These machines are designed to operate at high speeds, significantly reducing production time. This efficiency is crucial in meeting tight deadlines associated with construction projects.

2. Cost-Effective By streamlining the production process, custom glazed tile roll forming machines help lower manufacturing costs. The ability to produce tiles on demand also minimizes waste and excess inventory.

3. Quality Control Automation in the forming process enhances quality control, ensuring that each tile meets the specifications and standards required. Manufacturers can produce consistently high-quality products that are less prone to defects.

4. Customization As the name suggests, custom machines allow for the creation of tailored solutions. This is particularly important in today’s market, where consumers increasingly seek unique designs that reflect their personal tastes or branding requirements.

5. Sustainability Many modern tile machines are designed with energy efficiency in mind. By reducing waste and improving energy consumption, these machines support sustainable manufacturing practices.

Conclusion

The custom glazed tile roll forming machine embodies innovation in the realm of tile production. As industries strive to meet the growing demands for high-quality and customizable products, these machines offer a practical and efficient solution. With the ability to produce beautiful, durable tiles at an accelerated pace while maintaining cost-effectiveness, they play an essential role in transforming how tiles are manufactured and supplied.

In a competitive environment, businesses that invest in such advanced machinery are better positioned to respond to market trends and consumer preferences, ensuring their success in the ever-evolving construction landscape. The future of tile production is bright, thanks to the capabilities and benefits provided by custom glazed tile roll forming machines.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025