Feb . 12, 2025 14:32

Back to list

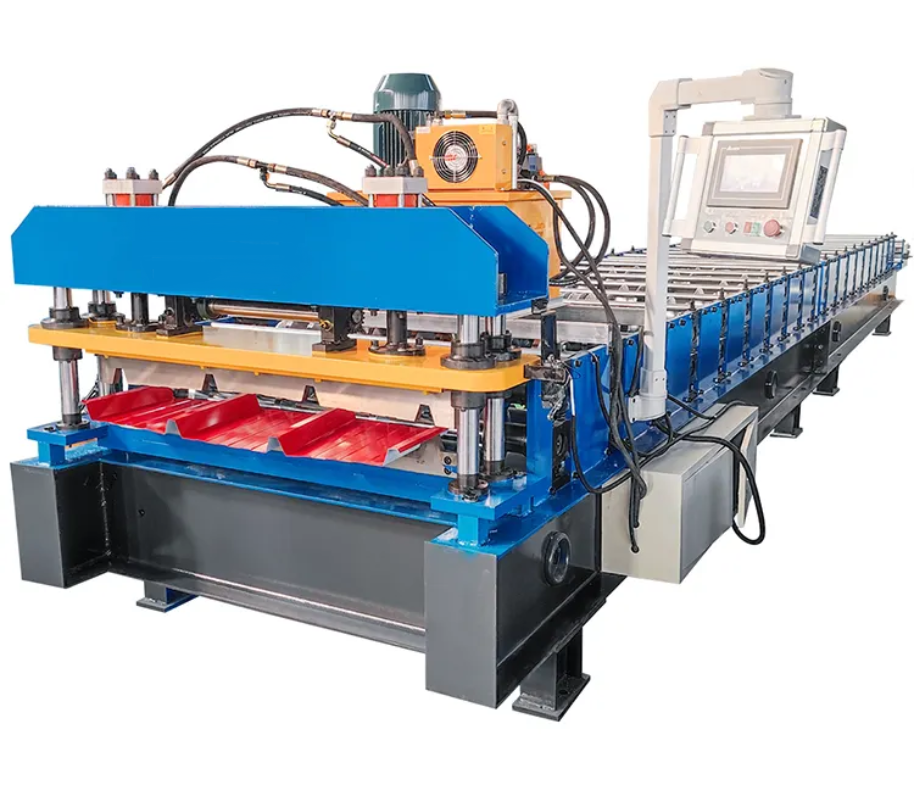

c shape roll forming machine

In the thriving world of industrial manufacturing, the C shape roll forming machine stands as a pivotal piece of equipment. Known for its precision and efficiency, it caters to the growing demand for high-quality metal components with a specific emphasis on C-shaped profiles. These machines are renowned for their remarkable ability to produce consistent, precise parts that meet stringent industry standards, making them indispensable in various sectors, including automotive, construction, and infrastructure development.

The authority of the C shape roll forming machine can be gauged by its widespread adoption across industries. It has revolutionized the way metal components are manufactured, offering a reliable solution for producing uniform and custom-shaped metal profiles swiftly and economically. This authoritative position is backed by the machine's adaptability; it can handle varying material grades from lightweight aluminum to sturdy steel, making it suitable for applications requiring different strength and durability parameters. Trustworthiness is cemented through the machine's consistent output quality and efficiency. Manufacturers who invest in high-end C shape roll forming machines benefit from reduced material wastage, lower production costs, and faster turnaround times. Furthermore, the machine's precision reduces the likelihood of defective products, thereby enhancing trust between manufacturers and their clients. Companies leveraging these machines often find themselves better positioned in competitive markets, thanks to the reliability and quality assurance they can offer. In conclusion, the C shape roll forming machine is more than just a manufacturing tool; it's a cornerstone of modern industry that exemplifies experience, expertise, authority, and trustworthiness. As industries continue to evolve with a focus on sustainability and efficiency, the role of such machines is set to expand, underscoring their significance in the production of high-quality metal components. For those looking to invest in a C shape roll forming machine, understanding its operational mechanics and maintenance needs is crucial for optimizing its capabilities and achieving a competitive edge in the marketplace.

The authority of the C shape roll forming machine can be gauged by its widespread adoption across industries. It has revolutionized the way metal components are manufactured, offering a reliable solution for producing uniform and custom-shaped metal profiles swiftly and economically. This authoritative position is backed by the machine's adaptability; it can handle varying material grades from lightweight aluminum to sturdy steel, making it suitable for applications requiring different strength and durability parameters. Trustworthiness is cemented through the machine's consistent output quality and efficiency. Manufacturers who invest in high-end C shape roll forming machines benefit from reduced material wastage, lower production costs, and faster turnaround times. Furthermore, the machine's precision reduces the likelihood of defective products, thereby enhancing trust between manufacturers and their clients. Companies leveraging these machines often find themselves better positioned in competitive markets, thanks to the reliability and quality assurance they can offer. In conclusion, the C shape roll forming machine is more than just a manufacturing tool; it's a cornerstone of modern industry that exemplifies experience, expertise, authority, and trustworthiness. As industries continue to evolve with a focus on sustainability and efficiency, the role of such machines is set to expand, underscoring their significance in the production of high-quality metal components. For those looking to invest in a C shape roll forming machine, understanding its operational mechanics and maintenance needs is crucial for optimizing its capabilities and achieving a competitive edge in the marketplace.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products