c shape purlin roll forming machine

C-Shape Purlin Roll Forming Machine An Overview

In the evolving landscape of modern construction and manufacturing, efficiency and precision are paramount. One of the pivotal machines that have emerged to meet these demands is the C-shape purlin roll forming machine. This equipment plays a crucial role in producing C-shaped purlins, which are significant structural components used in various applications, including buildings, warehouses, and bridges.

What is a C-Shape Purlin?

C-shape purlins are horizontal beams used primarily in the construction of steel structures. Their design resembles the letter C, which provides excellent strength and support for roofs and walls. These purlins serve as support for roofing sheets or panels, significantly enhancing the overall stability and durability of the structure. Their characteristics, such as lightweight, corrosion resistance, and ease of installation, make them an ideal choice in construction projects where structural integrity and cost-effectiveness are essential.

The Role of the Roll Forming Machine

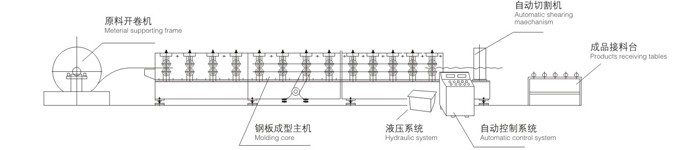

A C-shape purlin roll forming machine is specifically designed to manufacture these C-shaped components through a continuous process. The machine operates by uncoiling a flat strip of steel and passing it through a series of rollers. As the strip moves along the machine, the rollers gradually shape the flat steel into the desired C profile. This method not only ensures uniformity in the product but also enhances production efficiency compared to traditional fabrication methods.

Key Features

1. High Precision One of the most significant advantages of the C-shape purlin roll forming machine is its ability to produce highly precise profiles. The machine is equipped with advanced control systems that monitor the forming process, ensuring that each purlin meets the specified dimensions and quality standards.

c shape purlin roll forming machine

2. Versatility Many roll forming machines offer adjustable settings, allowing operators to produce different sizes and thicknesses of C-purlins. This adaptability means that manufacturers can cater to various construction needs without investing in multiple machines.

3. Speed and Efficiency The roll forming process enables high-speed production, making it possible to produce large quantities of purlins in a relatively short time. This efficiency leads to reduced labor costs and quicker project completion times.

4. Durability The heavy-duty construction of these machines ensures longevity and continuous operation, even under demanding conditions. Quality materials used in the machine's manufacturing contribute to its durability and reliability.

5. User-Friendly Operation Modern C-shape purlin roll forming machines are designed with user-friendly interfaces. Operators can easily program the machine for different profiles and monitor the production process without the need for extensive training.

Applications

C-shaped purlins produced by roll forming machines are extensively used across various sectors. In the construction industry, they form the backbone of many buildings, providing support for roofs, allowing for efficient drainage and ventilation. Their lightweight nature reduces the overall weight of structures, thus minimizing foundation costs. Additionally, these purlins are frequently used in the agricultural sector for constructing barns and storage facilities, as well as in the manufacturing of frames for solar panels.

Conclusion

In summary, the C-shape purlin roll forming machine is an indispensable tool in the modern construction industry. Its capability to produce high-quality, precise, and versatile C-shaped purlins contributes significantly to the structural integrity of various applications. As the demand for efficient building solutions continues to grow, investing in advanced roll forming technology becomes increasingly vital for manufacturers aiming to enhance productivity and meet market needs. With continuous advancements in technology, the future of C-purlin production looks promising, paving the way for even more innovative applications in construction and design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025