Supplier of C Section Purlin Production Machines for Efficient Steel Fabrication

C-Section Purlin Machine Supplier Revolutionizing the Steel Structure Industry

In recent years, the construction industry has seen a significant shift towards the use of steel for a variety of applications. Among the various steel products, C-section purlins have gained immense popularity due to their structural integrity, cost-effectiveness, and versatility. As demand for these components continues to rise, the need for advanced machinery to manufacture them efficiently has opened up a new market for C-section purlin machine suppliers.

C-section purlins are horizontal members used in a building’s framework to support the roof and wall cladding. They play a crucial role in the structural stability of modern buildings, especially in commercial and industrial applications. The significance of these purlins has led to an increased demand for machines that can produce them swiftly and accurately. This is where C-section purlin machine suppliers come into play.

What is a C-Section Purlin Machine?

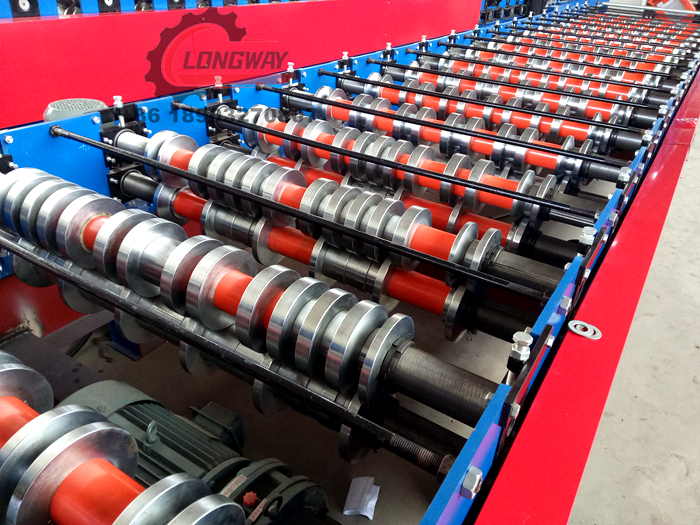

A C-section purlin machine is a specialized piece of equipment that produces C-shaped steel profiles from steel coils. The process typically involves uncoiling the steel, feeding it into a series of rollers, and then bending it into the desired C shape. These machines can produce high-quality purlins with precision, ensuring that they meet the specific requirements of various construction projects.

Modern C-section purlin machines are often automated and may include features such as programmable controls, adjustable settings for different dimensions, and the ability to produce varying thicknesses of steel. This automation not only enhances production efficiency but also reduces labor costs, making it an attractive investment for manufacturers.

Choosing the Right Supplier

In the burgeoning market for C-section purlin machines, selecting the right supplier is crucial for ensuring quality and reliability. A reputable supplier should possess several key characteristics

1. Experience and Expertise A supplier with extensive experience in the industry will have a better understanding of customer needs and market trends. They should also possess knowledge of the latest technology and techniques in purlin manufacturing.

c section purlin machine supplier

2. Quality Assurance The quality of the machinery is paramount. Suppliers should provide machines that meet international quality standards and come with warranties. This not only guarantees performance but also longevity.

3. Customer Support Effective after-sales service is essential for addressing any issues that may arise post-purchase. Suppliers should offer comprehensive customer support, including installation, training, and repair services.

4. Customization Options Different construction projects may require unique specifications. A good supplier should offer customizable machines that can adapt to varying production requirements.

5. Competitive Pricing While cost should not be the only consideration, it is an important factor. Suppliers should offer transparent pricing and help customers to understand the value proposition of their products.

The Future of C-Section Purlin Manufacturing

As the construction industry evolves, the demand for C-section purlins is expected to grow further. Emerging technologies such as computer-aided design (CAD), artificial intelligence (AI), and smart manufacturing are set to enhance the efficiency and precision of purlin manufacturing. Suppliers who invest in the latest technologies will not only streamline their operations but also provide better products to their clients.

Moreover, with the growing emphasis on sustainability, manufacturers are increasingly looking for ways to reduce waste and consume less energy during production. C-section purlin machine suppliers who prioritize eco-friendly practices and innovations are likely to have a competitive edge in the market.

In conclusion, C-section purlin machines are pivotal to the modern construction industry, and choosing the right supplier can greatly impact the success of manufacturing operations. As the sector continues to grow, suppliers who prioritize quality, innovation, and customer satisfaction will emerge as leaders in the market, helping to shape the future of steel construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025