c purlin roll forming machine price factory

Understanding C Purlin Roll Forming Machine Prices and Factors Affecting Them

C purlin roll forming machines play a crucial role in the production of C-shaped steel sections that are widely used in construction and various industrial applications. As demand increases for these efficient structures, understanding the pricing of C purlin roll forming machines becomes essential for businesses looking to invest in this technology.

What is a C Purlin Roll Forming Machine?

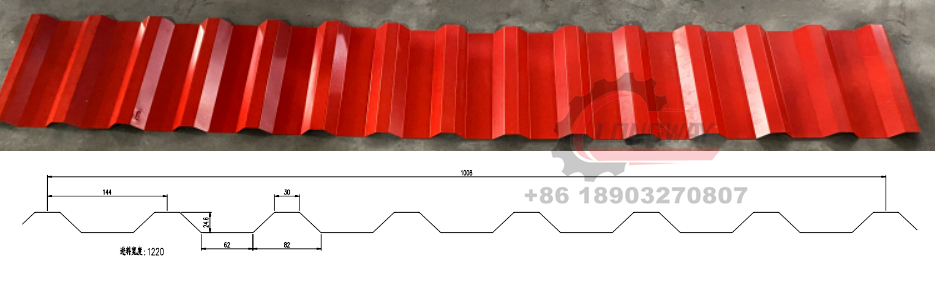

A C purlin roll forming machine is designed to manufacture C purlins from metal coils. The process involves feeding a metal coil through a series of rollers that shape it into the desired C-section profile. These machines can produce purlins of varying lengths and thicknesses, catering to different construction needs. The efficiency of this machinery ensures that producers can maintain a steady supply of high-quality purlins, significantly reducing manual labor and production time.

Factors Influencing Prices

1. Quality and Brand The price of a C purlin roll forming machine can vary significantly based on the manufacturer’s reputation. Established brands that are known for their quality and reliability generally command higher prices due to their advanced technology and after-sales support. It is essential to consider the long-term benefits of investing in a reputable machine versus seeking lower-cost alternatives.

c purlin roll forming machine price factory

2. Machine Specifications The technical specifications of the machine, including its production capacity, the thickness and width of the material it can process, and the number of forming stations, will directly impact its price. Machines capable of handling larger volumes or producing more complex profiles typically come at a higher cost.

3. Customization Some manufacturers offer customized machines tailored to specific production needs. Customization can include the addition of features like automated controls, enhanced safety elements, or integrated cutting systems. While customized machines tend to be more expensive, they can greatly enhance operational efficiency and reduce labor costs.

4. Materials Used The materials used in the construction of the roll forming machine also influence its price. Machines made from high-grade steel and featuring advanced coatings for durability may have a higher upfront cost but can offer significant return on investment through reduced maintenance and longer service life.

5. Supplier Location Geographical factors play a role in pricing as well. Machines sourced from local suppliers may incur lower shipping and import fees, while international suppliers may offer competitive pricing but involve additional logistics costs.

Conclusion

When considering the investment in a C purlin roll forming machine, it is crucial to evaluate the pricing in the context of features, quality, and production capabilities. By carefully assessing your specific needs and the attributes of different machines, you can make a more informed decision, ensuring that the equipment you choose aligns with your business objectives and budget. Ultimately, understanding the factors that influence the price of these machines will guide you in making an investment that pays off through efficiency and productivity in your operations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025