c purlin roll forming machine price

Understanding the Price of C Purlin Roll Forming Machines

In the world of metal fabrication, C purlin roll forming machines have emerged as essential tools for producing high-quality C purlins efficiently. These machines offer significant advantages in the construction and building industry, particularly when it comes to lightweight yet durable structural components. However, one of the most critical factors for businesses considering the investment in such machinery is understanding the price of C purlin roll forming machines.

What is a C Purlin Roll Forming Machine?

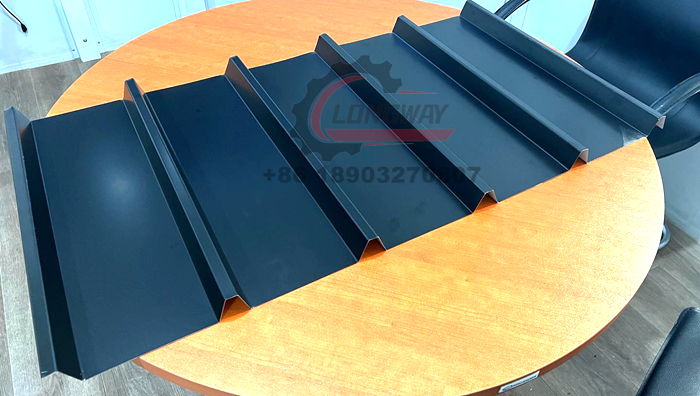

A C purlin roll forming machine is designed to transform flat metal sheets into C-shaped purlins through a series of forming rolls. These purlins are commonly utilized in the construction of commercial and industrial buildings, providing structural support for roofs and walls. The machines can produce purlins of various sizes and thicknesses, making them versatile for different applications.

Factors Influencing the Price

The price of C purlin roll forming machines can vary widely based on several factors

1. Machine Specifications The complexity and capability of the machine significantly impact the price. Machines that can produce a wider range of sizes or have more advanced features—such as automated controls or higher production speeds—tend to be more expensive.

2. Material Type and Thickness The materials that these machines can handle also influence their pricing. Machines designed to work with thicker or more robust materials may come at a premium due to the additional engineering and durability required.

c purlin roll forming machine price

3. Brand and Manufacturer Renowned manufacturers with a history of reliability and quality typically charge more for their machines. Investing in a reputable brand can offer better after-sales support and warranty options, which can protect your investment in the long run.

4. Customization Options Many manufacturers offer customization options to better suit the specific needs of their clients. Customized machines, which can cater to unique production requirements or specific material types, often come at a higher price.

5. Market Demand Like any commodity, the prices of C purlin roll forming machines can fluctuate based on market demand and economic conditions. During periods of high construction activity, prices may rise due to increased demand for manufacturing equipment.

General Price Range

Generally, the price for a standard C purlin roll forming machine ranges from $20,000 to $100,000, depending on the aforementioned factors. Entry-level models with basic features may start at the lower end, while high-capacity, customizable machines can reach the higher end of the price spectrum. It's crucial for potential buyers to conduct thorough market research and compare models to find an option that fits their budget while meeting their production needs.

Conclusion

Investing in a C purlin roll forming machine can be a substantial financial commitment, but understanding the factors influencing price can help businesses make informed decisions. By considering specific requirements and conducting attentive research into the models available, companies can find a machine that offers the best balance between cost, quality, and functionality. As the demand for C purlins continues to grow, having the right equipment can help businesses stay competitive in the market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025