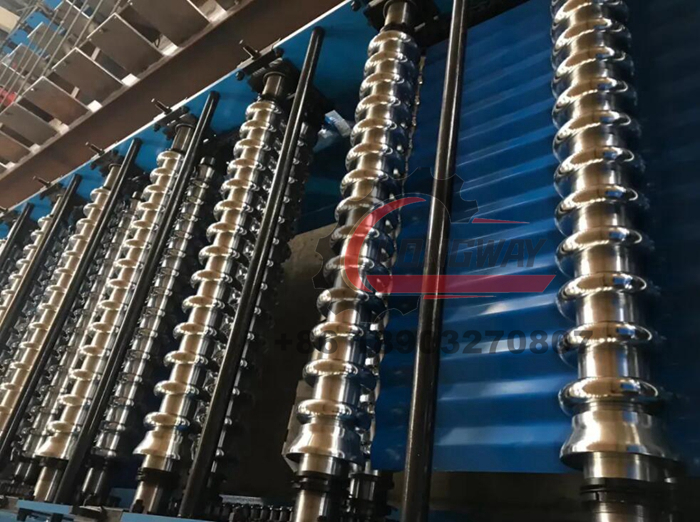

c purlin making machine

The C Purlin Making Machine An Overview

In the world of construction and manufacturing, the demand for efficient, high-strength structural components has led to the development of specialized machinery designed to produce these elements with precision and speed. Among the notable innovations is the C purlin making machine, a vital piece of equipment used for producing C-shaped steel purlins, which serve as critical framing components in various structures.

What is a C Purlin?

A C purlin is a structural element made of steel that resembles the letter C in cross-section. Its unique shape provides strength and stability, making it an ideal choice for supporting walls, roofs, and other building components. C purlins are widely used in the construction of warehouses, commercial buildings, and agricultural structures due to their lightweight yet durable nature.

The Importance of C Purlin Making Machines

The C purlin making machine automates the process of manufacturing C purlins, significantly enhancing productivity and reducing labor costs. Traditional methods of producing purlins can be time-consuming and require skilled labor, but with modern machinery, manufacturers can produce high-quality purlins in varying sizes and thicknesses with minimal manual intervention.

Key Features of C Purlin Making Machines

1. Automation and Control Modern C purlin making machines often come with advanced control systems that automate the entire process, from cutting to forming. This ensures consistency in quality and size, making it easier to meet specific project requirements.

c purlin making machine

2. Versatile Production Many machines are designed to produce purlins of different dimensions and specifications. This versatility allows manufacturers to cater to a broader market and adapt to changing customer needs.

3. Material Efficiency With precise cutting and forming capabilities, C purlin making machines minimize waste, ensuring that materials are used efficiently. This not only reduces costs but also supports environmentally friendly manufacturing practices.

4. Speed and Efficiency These machines are engineered to operate at high speeds, enabling manufacturers to produce large quantities of purlins in a short amount of time. This rapid production capacity is crucial for meeting tight project deadlines.

5. Durability and Reliability Constructed from high-quality materials, C purlin making machines are designed for longevity and can withstand the demands of continuous operation. Regular maintenance and appropriate use can extend the lifespan of the machine, ensuring a good return on investment.

Applications of C Purlins

C purlins produced by C purlin making machines find their applications across various sectors. In commercial construction, they are used for the framework of buildings and warehouses, providing essential support for roofs and walls. In agricultural settings, C purlins are employed in the construction of barns and storage facilities. Additionally, these purlins are also used in the manufacturing of prefabricated buildings, where modular designs require precision-engineered components.

Conclusion

The C purlin making machine represents a significant advancement in the field of construction and manufacturing. By facilitating the efficient production of high-quality purlins, this machinery plays a crucial role in supporting the modern construction industry. As technology continues to evolve, we can expect further enhancements in the capabilities of C purlin making machines, leading to even greater efficiency and sustainability in building practices. Investing in such machines is not only a step towards enhancing operational capabilities but also a commitment to meeting the growing demand for reliable and durable construction materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025