c purlin machine manufacturers manufacturers

The Role of C Purlin Machine Manufacturers in Modern Construction

In the rapidly evolving construction industry, efficiency and cost-effectiveness are paramount. Among the critical components contributing to the structural integrity of modern buildings are metal purlins, particularly C purlins. C purlins are widely used for creating a strong framework in various construction applications, including industrial buildings, warehouses, and agricultural structures. This article explores the significance of C purlin machine manufacturers in the context of contemporary construction.

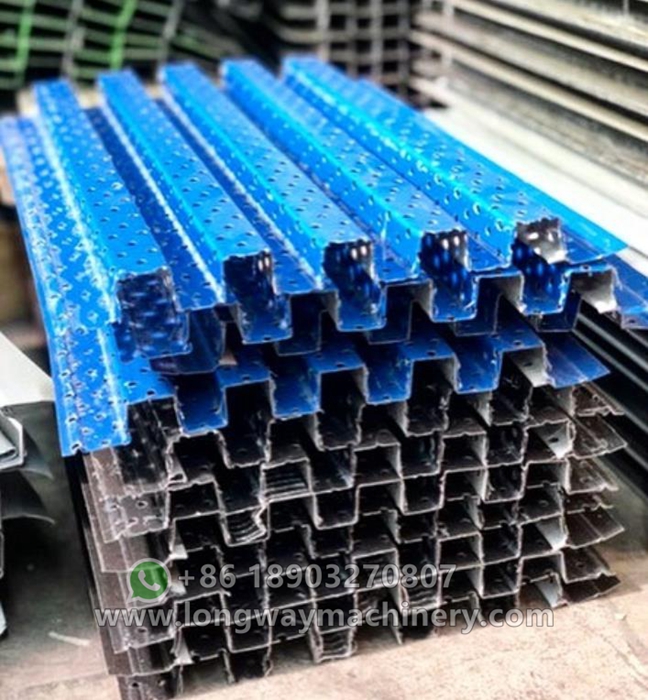

Understanding C Purlins

C purlins are horizontal supports that help in the framing of walls or roofs. Their unique C shape allows them to provide excellent load-bearing capacity while being lightweight and easy to handle. They are manufactured from high-quality steel and come in a variety of sizes to suit different construction needs. The demand for C purlins is driven by the growing trend of steel structures, owing to their durability and resistance to various environmental factors.

The Importance of C Purlin Machine Manufacturers

C purlin machine manufacturers play a crucial role in the production of these essential structural components. They specialize in designing and producing machines that can efficiently fabricate C purlins from raw materials. These manufacturers cater to the needs of construction businesses by supplying state-of-the-art machinery that enhances productivity and ensures consistent quality.

1. Advanced Technology

The evolution of technology has revolutionized the manufacturing process of C purlins. Leading manufacturers are incorporating advanced techniques such as computer numerical control (CNC) in their machines. CNC technology allows for precise cutting, bending, and shaping of metal, reducing material wastage and ensuring that each unit meets exact specifications. This technological advancement not only increases efficiency but also enhances safety in the manufacturing process.

2. Customization and Versatility

One of the significant advantages offered by C purlin machine manufacturers is the ability to customize production lines based on client requirements. Different construction projects may necessitate specific sizes and thicknesses of C purlins. Manufacturers can design machines that produce purlins tailored to these needs, thereby providing versatility in the market. This adaptability ensures that builders can obtain precise materials for their specific projects without having to compromise on quality.

c purlin machine manufacturers manufacturers

3. Cost Efficiency

Investing in C purlin machines can lead to significant cost savings for construction companies. By producing purlins in-house, companies can lower procurement costs, minimize inventory handling, and reduce lead times. Moreover, automated production lines make it easier to scale production up or down based on demand, allowing businesses to manage their resources effectively. Manufacturers also offer competitive pricing on their machinery, making it an attractive option for companies looking to enhance production capabilities without sacrificing budget constraints.

Quality Control and Standards

Quality is of utmost importance in the manufacturing of C purlins. Reputable C purlin machine manufacturers adhere to strict quality control measures and industry standards. They conduct tests on the machines and final products to ensure they meet national and international benchmarks. This commitment to quality helps construct safe and reliable structures, ultimately enhancing the reputation of the builders and engineers who utilize these materials.

Market Trends and Future Prospects

The global push towards sustainable construction practices is also influencing trends in C purlin manufacturing. As environmental concerns rise, manufacturers are increasingly focusing on producing energy-efficient machines that minimize waste and utilize recyclable materials. Furthermore, the integration of smart technologies such as the Internet of Things (IoT) in manufacturing processes is paving the way for real-time monitoring and improved operational efficiencies.

The future of C purlin machine manufacturers looks promising as the demand for prefabricated construction solutions continues to rise. With ongoing innovations and a focus on sustainability, manufacturers are well-positioned to meet the needs of a changing market, while also contributing to more efficient and environmentally friendly construction practices.

Conclusion

C purlin machine manufacturers serve as a backbone for the growing demand for C purlins in modern construction. Through technological advancements, customization options, and a commitment to quality, they play a vital role in ensuring that construction projects are not only cost-effective but also reliable and durable. As the industry progresses toward more sustainable practices, the collaboration between manufacturers and construction companies will be crucial in shaping the future of building construction. Their partnership will ultimately lead to stronger, more resilient structures that meet the challenges of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025