c purlin machine manufacturers manufacturer

Exploring the Landscape of C Purlin Machine Manufacturers

The construction and manufacturing sectors are consistently evolving with the introduction of advanced machinery designed to enhance production efficiency. Among these innovations, the C purlin machine has gained significant traction, particularly in the steel fabrication industry. These machines are pivotal in manufacturing C purlins—essential structural components used extensively in various construction applications.

What is a C Purlin?

C purlins are integral to the framework of buildings, providing necessary support to roofing and are often used in the construction of warehouses, factories, and commercial buildings. These components are typically fabricated from high-quality steel, ensuring durability and strength. The C shape allows for load distribution, offering resilience against bending and twisting forces in structural contexts.

The Role of C Purlin Machines

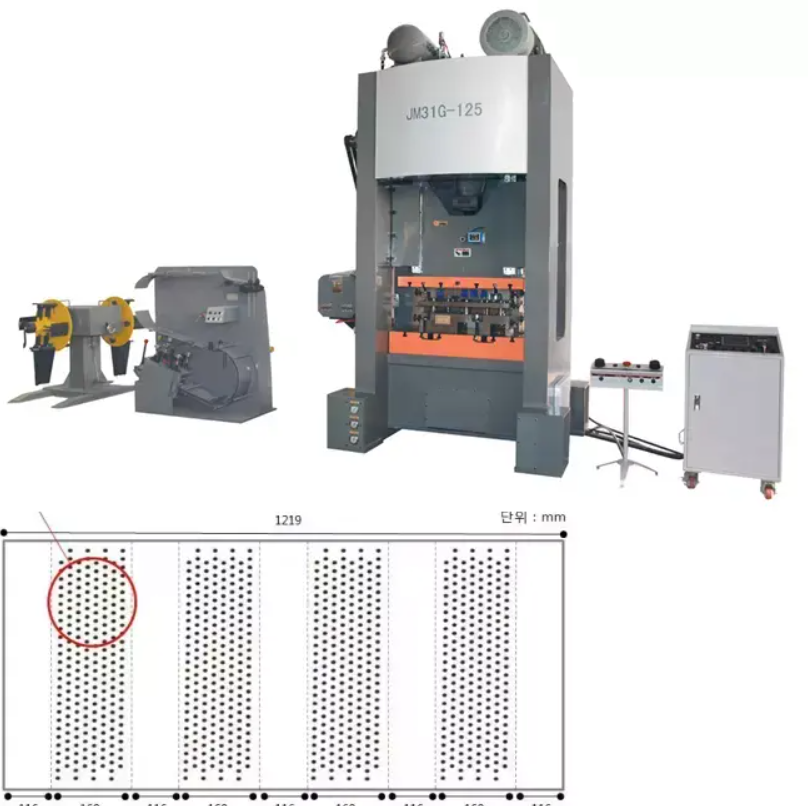

C purlin machines are specialized equipment designed to produce these purlins efficiently. They work through the process of roll forming, where flat steel strips are gradually shaped into C purlins through a series of rollers and dies. This process not only streamlines production but also maximizes material utilization, minimizing waste—an essential factor in modern manufacturing practices.

Key Features of C Purlin Machines

Manufacturers of C purlin machines emphasize several key features that differentiate their products in the marketplace. Among these are

1. Automation Advanced machinery is often fully automated, reducing the need for manual labor and allowing for high-speed production. Automation also enhances precision, ensuring that each purlin produced meets stringent quality criteria.

c purlin machine manufacturers manufacturer

3. User-Friendly Design Modern C purlin machines often feature intuitive control systems, making them easier to operate. This ease of use can significantly reduce training time for new employees and improve overall operational efficiency.

4. Durability and Maintenance The best machines are constructed from high-grade materials to ensure longevity. Additionally, manufacturers often design them for easy maintenance, with accessible components that simplify routine checks and repairs.

The Market for C Purlin Machine Manufacturers

A multitude of manufacturers exists globally, each vying for a share of this competitive market. Some of the leading C purlin machine manufacturers have carved out reputations through innovation, quality, and customer service. Countries such as China, India, and various European nations are prominent players in this industry, equipped with state-of-the-art technology and experienced professionals.

Many manufacturers also offer customization options, allowing customers to tailor machines to fit specific production needs. This bespoke approach enables businesses to maximize their operational efficiency and meet particular project requirements without compromising on quality.

The Future of C Purlin Machines

As the construction industry shifts towards sustainability and efficiency, the demand for C purlin machines is projected to grow. Manufacturers are increasingly focusing on incorporating eco-friendly technologies and materials. Innovations such as energy-efficient designs and the capability to use recycled steel not only meet regulatory standards but also appeal to environmentally conscious consumers in the construction sector.

Additionally, the integration of Industry 4.0 technologies, such as IoT and AI, into manufacturing processes is set to revolutionize how C purlin machines operate. These technologies can provide real-time data, predictive maintenance alerts, and enhanced quality control, further streamlining production workflows.

Conclusion

The C purlin machine is a cornerstone of modern steel fabrication, playing a crucial role in the construction industry. With numerous manufacturers striving to differentiate themselves through innovation and quality, the landscape of C purlin machines is dynamic and evolving. As businesses continue to prioritize efficiency and sustainability, the future of C purlin machine manufacturing looks promising, paving the way for more advancements in this essential sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025