c purlin machine

Understanding C Purlin Machines A Comprehensive Overview

In the realm of modern construction and engineering, the efficiency and precision of building materials are of paramount importance. One such crucial material is the C purlin, a structural steel component widely used in the construction of buildings, particularly for roofing and wall support. To produce these essential components, manufacturers rely on specialized machinery known as C purlin machines.

What is a C Purlin?

Before diving into the machinery, it is essential to understand what a C purlin is. A C purlin is a horizontal structural member shaped like the letter C. These sections are typically made of hot-rolled or cold-formed steel and serve as vital components in a building's framework. They provide support for various structures such as roofs, walls, and flooring systems by transferring loads to columns or walls. Their design offers high strength and light weight, making them ideal for a wide range of applications.

The Role of C Purlin Machines

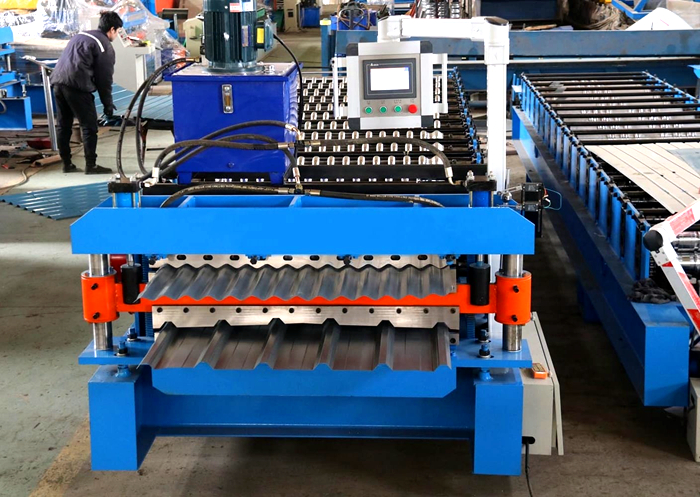

C purlin machines are specialized pieces of equipment that automate the production of C purlins. They optimize the manufacturing process, allowing for quick and efficient production, which translates to reduced labor costs and increased output. These machines can be configured to produce various sizes and thicknesses of C purlins, catering to the specific needs of different construction projects.

Key Features of C Purlin Machines

1. Automation Modern C purlin machines are highly automated, often operated through computer numerical control (CNC) systems. This automation ensures precision in cutting, forming, and punching processes, resulting in high-quality purlins.

2. Versatility Many C purlin machines are designed to produce not only C purlins but also other types of purlins, such as Z purlins. This versatility allows manufacturers to expand their product lines without investing in additional machinery.

3. Speed and Efficiency These machines are engineered for high-speed production. With the capability to produce several meters of purlins per minute, C purlin machines significantly enhance the efficiency of the manufacturing process.

4. Customizability C purlin machines can often be adjusted to accommodate various specifications, such as width, height, and thickness, ensuring that manufacturers can meet diverse client requirements.

5. Integrated Systems Many modern machines come equipped with integrated systems for material handling, cutting, and forming, which streamlines the entire production process from start to finish.

The Production Process

c purlin machine

The operation of a C purlin machine typically involves the following steps

1. Material Feeding Steel coils are fed into the machine, which unrolls and straightens the material.

3. Forming The flat steel strips are then shaped into the C profile through a series of rollers, ensuring precise dimensions.

4. Cutting After forming, the purlins are cut to the required lengths.

5. Quality Control Finally, the produced purlins undergo quality checks to ensure they meet the specified standards before packaging.

Advantages of Using C Purlin Machines

Utilizing C purlin machines in manufacturing offers several advantages

- Cost-Effectiveness By streamlining production and reducing labor costs, these machines can significantly lower overall manufacturing expenses.

- Quality Assurance The precision of automated machines leads to consistent and high-quality products, minimizing waste due to defects.

- Increased Capacity With high-speed capabilities, manufacturers can meet growing demands efficiently, helping them seize opportunities in a competitive market.

Conclusion

In conclusion, C purlin machines play an indispensable role in the construction industry, providing the means to produce high-quality, versatile, and cost-effective purlins. As the demand for efficient building materials continues to grow, the importance of such machinery will only increase. Innovations in automation and design will further enhance their capabilities, ensuring that they remain integral to modern construction practices. Whether for commercial, industrial, or residential projects, C purlin machines are vital for the structural integrity and efficiency of contemporary construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025