C Purlin Forming Machine Manufacturers and Their Key Features

Understanding C Purlin Forming Machine Factories

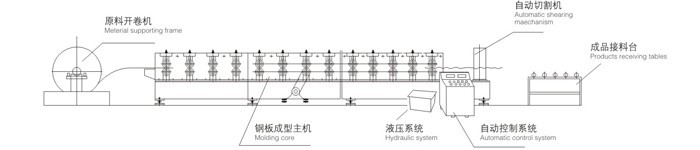

C purlin forming machines play a vital role in the manufacturing sector, particularly in the production of purlins used in steel structures. These machines are designed to convert raw metal strips into C-shaped purlins through a series of automated processes, ensuring efficiency and precision. This article explores the significance of C purlin forming machine factories and their contribution to the construction and fabrication industries.

Understanding C Purlin Forming Machine Factories

One of the core advantages of C purlin forming machines is their automation. These machines are equipped with features that allow for continuous operation and minimal human intervention, which enhances production speed while reducing labor costs. The automated process includes feeding raw material into the machine, forming it into the desired shape, and cutting it to the necessary lengths. This streamlining of production not only boosts efficiency but also aids in maintaining consistency across all products.

c purlin forming machine factories

Moreover, C purlin forming machine factories typically focus on customizability. Manufacturers often have unique requirements based on their architectural designs. With advanced forming machines, factories can produce purlins in various sizes and thicknesses, tailoring them to meet specific project needs. This flexibility is crucial in the construction industry, where adaptability to design changes is common.

Quality control is another significant aspect of operations within C purlin forming machine factories. To ensure that the final products adhere to industry standards, rigorous testing is conducted throughout the manufacturing process. This includes examining the mechanical properties of the metal, checking for dimensional accuracy, and ensuring the integrity of the welds. By maintaining high standards, these factories contribute to the overall safety and longevity of the structures that utilize their purlins.

Furthermore, the growth of the construction industry has led to an increased demand for high-quality building materials. C purlin forming machine factories are well-positioned to meet this demand, as they offer not only mass production capabilities but also scalable solutions. As construction projects grow in size and complexity, the ability to produce large volumes of purlins quickly becomes essential.

In conclusion, C purlin forming machine factories play a crucial role in the manufacturing of building materials that are essential for modern construction. Their ability to produce high-quality, customizable, and reliable purlins efficiently makes them indispensable to the industry. As technology advances and the demand for steel structures continues to rise, these factories will remain at the forefront of innovation and production in the construction market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025