C Section Purlin Roll Forming Equipment for Efficient Construction Solutions

Understanding C Purlin Forming Machines

C purlin forming machines are specialized equipment used in the manufacturing of C-shaped metal profiles, commonly known as purlins. These profiles play a critical role in construction and industrial applications, particularly in building frameworks, support structures, and roof trusses. With their unique shape and high strength-to-weight ratio, C purlins are indispensable in the modern construction industry. In this article, we will explore the functions, advantages, and features of C purlin forming machines.

What is a C Purlin?

Before delving into the forming machines, it's essential to understand what C purlins are. C purlins are horizontal structural elements with a 'C' cross-section. They are typically made of steel, which provides durability and resistance to structural loads. The design of C purlins allows them to be used in both primary and secondary structural applications, as they can efficiently support loads and provide stability to various structures, including warehouses, factories, and commercial buildings.

The Functionality of C Purlin Forming Machines

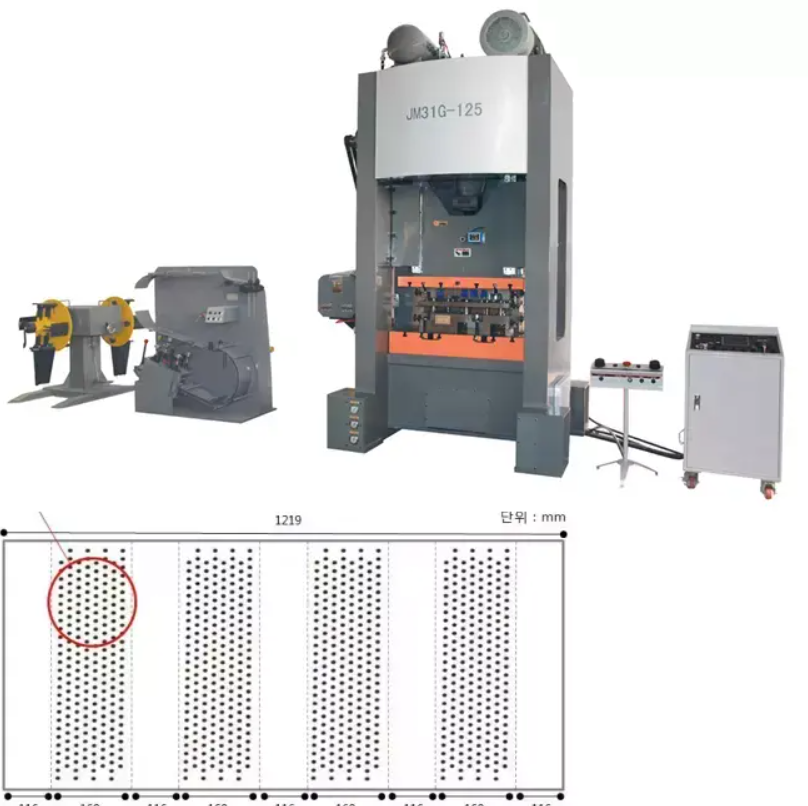

C purlin forming machines are designed to produce these steel profiles with precision and efficiency. The process usually involves several key steps, including

1. Coil Feeding The machine starts with a metal coil, usually made from high-strength steel. The coil is unwound and fed into the forming machine.

2. Roll Forming In this stage, the machine uses a series of rollers to shape the flat steel strip into a C profile. The rollers are strategically positioned to gradually bend and form the metal until it reaches the desired shape.

3. Cutting Once the metal has been fully formed into the C profile, the machine cuts it to the specified lengths. This ensures that the C purlins meet the size requirements for specific construction projects.

4. Stacking Finally, the formed and cut C purlins are stacked for easy handling and transportation.

Advantages of Using C Purlin Forming Machines

c purlin forming machine

Utilizing a C purlin forming machine offers multiple advantages for manufacturers and builders alike

1. Efficiency These machines allow for high-speed production, significantly reducing the time and labor required to create steel purlins. This is particularly beneficial for large-scale construction projects where time is of the essence.

2. Precision Advanced C purlin forming machines are equipped with computerized control systems that ensure each profile is manufactured with consistent accuracy. This precision is crucial in construction, where even minor discrepancies can lead to structural weaknesses.

3. Cost-Effective By streamlining the manufacturing process and reducing labor costs, using a C purlin forming machine can lead to substantial cost savings. Additionally, the durability of the produced purlins minimizes maintenance and replacement expenses over time.

4. Versatility C purlin forming machines can be adjusted to produce various sizes and thicknesses of purlins, making them suitable for diverse applications. This flexibility makes them an excellent investment for businesses that need to cater to different project specifications.

5. Quality Control These machines often come with integrated quality control features. This allows manufacturers to monitor critical parameters throughout the production process, ensuring that the final products meet stringent industry standards.

Key Features of C Purlin Forming Machines

When selecting a C purlin forming machine, it is essential to consider several features

- Automation Level Fully automated machines can enhance productivity and minimize human error. - Material Compatibility Some machines are designed to handle different materials such as galvanized steel, stainless steel, and more. - Power Requirements Understanding the energy needs of the machine is crucial for operational efficiency. - Maintenance Machines that require less frequent maintenance can save time and costs in the long run.

Conclusion

C purlin forming machines are vital in today's construction industry, providing a productive and efficient means of manufacturing high-quality C purlins. Their ability to integrate technology, improve precision, and reduce costs makes them essential for any manufacturer looking to enhance their production capabilities. As construction demands continue to evolve, investing in advanced C purlin forming machines will likely be a strategic decision that pays dividends in reliability and performance. Such innovations not only drive efficiency but also contribute to the overall safety and integrity of construction practices worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025