c purline roll forming machine factory

Understanding C Purline Roll Forming Machines Manufacturing and Applications

In the realm of modern construction and industrial processing, C purline roll forming machines play a pivotal role. These machines are engineered to produce C-shaped steel profiles, commonly known as purline, which are essential components used in various structural applications. This article delves into the significance of C purline roll forming machines, the manufacturing process, and their diverse applications across different industries.

What is a C Purline?

C purline is a type of structural steel member that is predominantly used in building frameworks, particularly for supporting roofs and walls. Its C-shaped cross-section provides excellent strength-to-weight ratios, making it a preferred choice in construction where structural integrity is paramount while minimizing material costs. The design allows for easy installation and versatile application in different structures, from warehouses to commercial buildings.

The Manufacturing Process

C purline roll forming machines are intricately designed to transform flat steel sheets into the required C-shape through a continuous bending process. The manufacturing process involves several key steps

1. Material Preparation High-quality cold-rolled or hot-rolled steel strips are used as raw materials. These strips are fed into the machine, where they are uncoiled, straightened, and cut to the desired length.

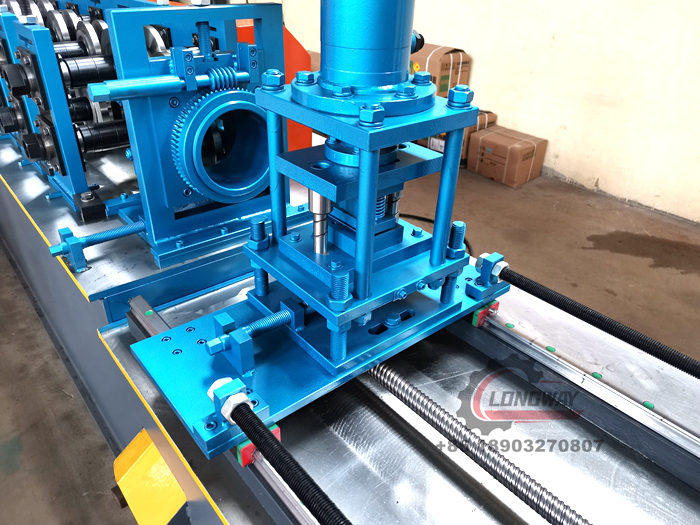

2. Roll Forming Process The core of the machine consists of several sets of rollers that progressively shape the steel strip into the desired C profile. Each set of rollers is meticulously designed to perform a specific bending operation. The combination of these rollers shapes the strip effectively without compromising its structural integrity.

3. Cutting and Finishing Once the metal has been formed, it is cut to length using integrated cutting tools. Additional processes such as punching or notching may occur, depending on the specific design and requirements of the purline.

4. Quality Control Throughout the process, quality control measures are implemented to ensure the finished product meets industry standards and specifications. This includes checking the dimensions, thickness, and overall finish of the C purline.

5. Packaging and Delivery After quality assurance, the purline is packaged securely and prepared for delivery to construction sites or warehouses.

Applications of C Purline

C purline products serve a multitude of purposes across various industries. Some of the most common applications include

c purline roll forming machine factory

- Roof Supports In commercial and industrial buildings, C purlines provide essential support for roofing systems, enhancing their strength and stability.

- Building Frameworks They are widely used in constructing the frameworks of warehouses, commercial spaces, and residential buildings, facilitating robust and secure structures

.- Agricultural Structures C purline is often utilized in the construction of greenhouses, barns, and other farming structures due to its ability to withstand environmental stresses.

- Signage and Shelters Lightweight yet durable, C purline is an ideal choice for building outdoor signage and temporary shelters, providing extensive design flexibility.

- Bridges and Walkways The structural integrity of C purlines makes them suitable for applications in pedestrian walkways and bridges, where safety is a primary concern.

Advantages of C Purline Roll Forming Machines

Investing in a C purline roll forming machine offers significant benefits to manufacturers and construction companies alike. These advantages include

- Efficiency The continuous production process enables high output while minimizing labor costs.

- Precision Automated systems ensure that each C purline produced conforms to exact specifications, reducing wastage and increasing quality.

- Customization Manufacturers can easily customize the size and thickness of the purline to meet specific requirements, enhancing versatility.

- Durability The resulting C purlines possess robust structural properties that extend their lifespan and reliability in various applications.

Conclusion

C purline roll forming machines represent a crucial innovation within the steel manufacturing sector. By streamlining the production process of C-shaped steel profiles, these machines support various industries, from construction to agriculture. As the demand for lightweight and durable construction materials continues to rise, the role of C purline roll forming machines is set to become even more significant, underpinning the growth of modern infrastructure around the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025