C Purlin Cold Roll Forming Equipment for Efficient Structural Solutions

Understanding C Purlin Cold Roll Forming Machines

Cold roll forming technology has become a fundamental component in the production of various metal profiles, particularly in the construction and manufacturing industries. Among the most popular products produced with this technology is the C purlin. This article delves into the C purlin cold roll forming machine, its functionality, advantages, and applications.

What is a C Purlin?

C purlins are horizontal structural members used in building frames, typically formed from cold-rolled steel. Their C-shaped profile provides excellent load-carrying capacity and is commonly used as a support system for roofs, walls, and other structural components. C purlins are preferred for their strength-to-weight ratio, ease of installation, and versatility in design.

The Cold Roll Forming Process

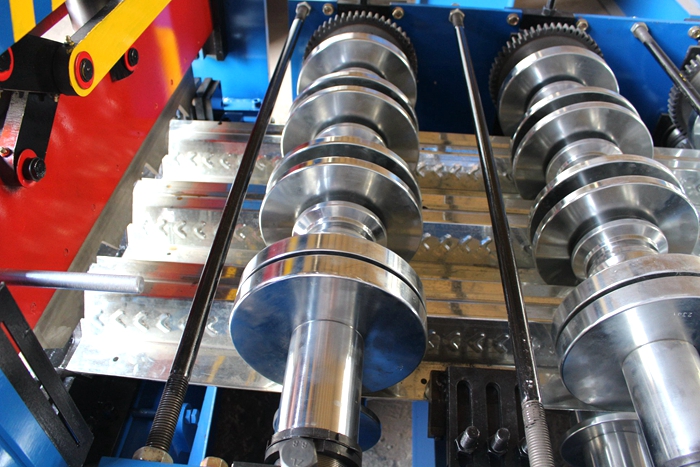

Cold roll forming is a highly efficient process that involves feeding a continuous strip of metal into a series of rollers that shape the metal into desired profiles without the need for heating. This method preserves the metal's properties, ensuring high strength and enhanced durability. The cold roll forming machine for C purlins consists of several key components

1. Uncoiler This device holds the coil of metal and feeds it into the roll forming system at the required speed. 2. Roll Forming System A series of rollers precisely shapes the metal into the C profile. The number of rollers and their arrangement depends on the specific design of the C purlin.

3. Cut-off Mechanism After the desired length is achieved, a cutting device separates the C purlin from the continuous strip.

Advantages of C Purlin Cold Roll Forming Machines

c purlin cold roll forming machine

C purlin cold roll forming machines offer numerous advantages

1. High Production Efficiency These machines can produce large quantities of C purlins in a short period. Continuous forming processes minimize material wastage and reduce production time.

2. Customizability Cold roll forming allows for tailored profiles to meet specific design requirements. By adjusting the roller settings, manufacturers can create purlins of varying sizes and specifications.

3. Cost-Effective Manufacturing The reduced need for extensive tooling and minimal material waste contribute to lower production costs. Furthermore, the lightweight nature of C purlins allows for easier handling and transport, reducing logistics expenses.

4. Superior Strength and Quality The cold forming process enhances the metal's mechanical properties, resulting in stronger and more durable purlins. Additionally, the high level of automation in the process leads to consistent quality and accuracy.

Applications of C Purlins

C purlins are extensively used in various sectors, including

- Building Construction They provide structural support for roofs, allowing for clear spans while maintaining structural integrity. - Manufacturing Facilities C purlins are used in the construction of factories and warehouses, offering flexibility for layout changes. - Agricultural Structures They serve as essential components in barns, storage facilities, and other agricultural buildings. - Infrastructure Projects These purlins are also utilized in bridges and other infrastructure developments, thanks to their ability to support significant loads.

Conclusion

In summary, C purlin cold roll forming machines play a vital role in the production of structural steel components essential for modern construction and manufacturing. With their efficiency, customizability, and superior quality output, these machines offer significant advantages to manufacturers looking to meet the growing demand for durable and cost-effective building materials. As the construction industry continues to evolve, the reliance on advanced technology like cold roll forming will only increase, cementing the importance of C purlins in contemporary engineering and architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025