Feb . 06, 2025 06:47

Back to list

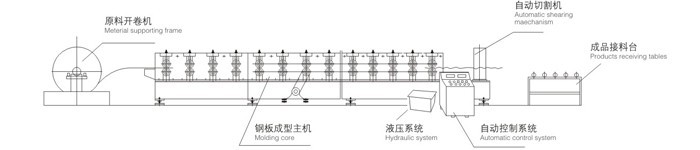

US Metal Roofing Ag and R panel Roll Former

A C profile steel roll forming machine represents an innovation in the metal fabrication industry, delivering precision and efficiency like no other. When selecting this machinery, understanding its multifaceted benefits, operational intricacies, and industry applications is paramount.

Trust in a C profile steel roll forming machine stems from its consistency in delivering precise outputs. Businesses report significant reductions in error rates and plant downtimes, attributing these improvements to the machine's robust build and advanced technology. The integration of automation features in modern machines has further augmented operational capabilities, allowing for remote monitoring and real-time adjustments. This capability ensures that the production process remains uninterrupted and outputs are of the highest quality. In practice, C profile steel roll forming machines are often hailed for their contribution to sustainable production practices. By optimizing material usage and incorporating processes that minimize energy consumption, they align with global efforts towards environmentally responsible manufacturing. Companies adopting these machines demonstrate a commitment to sustainability, enhancing their reputation and compliance with eco-friendly standards. To truly leverage the benefits of a C profile steel roll forming machine, companies must invest in ongoing training and support for their staff. This investment not only ensures safety and efficiency but also maximizes the return on investment. Partnerships with machine manufacturers or third-party experts offer invaluable resources for troubleshooting and advanced training, ensuring that teams remain at the forefront of industry advancements. In conclusion, the C profile steel roll forming machine is more than a piece of industrial equipment; it is a testament to engineering excellence and a catalyst for innovation in manufacturing. Its precision, efficiency, and sustainability make it an indispensable asset for businesses aiming to keep pace with the ever-evolving demands of the global market. By investing in this technology, companies position themselves as industry leaders, capable of delivering exceptional quality and value to their clients.

Trust in a C profile steel roll forming machine stems from its consistency in delivering precise outputs. Businesses report significant reductions in error rates and plant downtimes, attributing these improvements to the machine's robust build and advanced technology. The integration of automation features in modern machines has further augmented operational capabilities, allowing for remote monitoring and real-time adjustments. This capability ensures that the production process remains uninterrupted and outputs are of the highest quality. In practice, C profile steel roll forming machines are often hailed for their contribution to sustainable production practices. By optimizing material usage and incorporating processes that minimize energy consumption, they align with global efforts towards environmentally responsible manufacturing. Companies adopting these machines demonstrate a commitment to sustainability, enhancing their reputation and compliance with eco-friendly standards. To truly leverage the benefits of a C profile steel roll forming machine, companies must invest in ongoing training and support for their staff. This investment not only ensures safety and efficiency but also maximizes the return on investment. Partnerships with machine manufacturers or third-party experts offer invaluable resources for troubleshooting and advanced training, ensuring that teams remain at the forefront of industry advancements. In conclusion, the C profile steel roll forming machine is more than a piece of industrial equipment; it is a testament to engineering excellence and a catalyst for innovation in manufacturing. Its precision, efficiency, and sustainability make it an indispensable asset for businesses aiming to keep pace with the ever-evolving demands of the global market. By investing in this technology, companies position themselves as industry leaders, capable of delivering exceptional quality and value to their clients.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products