c profile roll forming machine factories

C Profile Roll Forming Machine Factories An Overview of the Industry

In the modern manufacturing landscape, efficiency and precision are paramount. One of the key technologies that have emerged to meet these demands is the roll forming process, particularly in the production of C profiles. C profile roll forming machines have become essential in various industries, including construction, automotive, and appliance manufacturing. This article explores the role of C profile roll forming machine factories, their operational principles, applications, and the benefits they offer.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, usually steel, is passed through a series of rollers. These rollers progressively shape the material into a desired profile, such as a C shape. The process is known for its efficiency, allowing for the production of long lengths of uniform profiles with tight tolerances. The resulting C profiles are widely used due to their strength, durability, and versatility.

The C Profile Roll Forming Machine

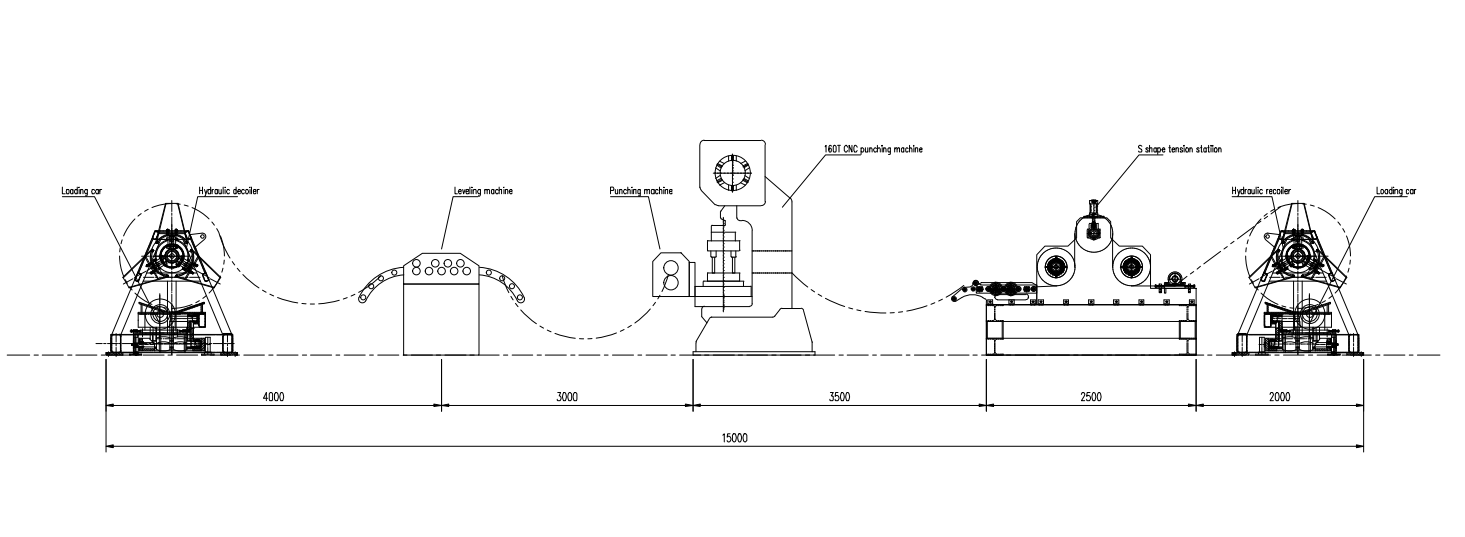

C profile roll forming machines are specialized equipment designed to produce C-shaped profiles from metal sheets or coils. The machines consist of several components, including a uncoiler, a roll forming section, cutting equipment, and a run-out table. The uncoiler unwinds the metal, which then passes through the roller system that gradually shapes the profile. Once the desired length is reached, the system cuts the material to the specified size.

The design of these machines can vary significantly based on the specific application and production requirements. Factories often customize their C profile roll forming machines to accommodate different material thicknesses, widths, and profile dimensions. Advanced models even incorporate automated controls and robotics to enhance efficiency and reduce labor costs.

Applications of C Profiles

C profiles have a wide range of applications across various sectors. In construction, they are commonly used as structural components in steel frameworks, roofing supports, and wall studs. Their shape provides excellent load-bearing capabilities, making them ideal for both residential and commercial buildings.

c profile roll forming machine factories

In the automotive industry, C profiles are employed in the manufacturing of chassis and structural components due to their high strength-to-weight ratio. Similarly, C profiles are utilized in the production of appliances, such as refrigerators and washing machines, where they serve as support structures or frames.

Benefits of C Profile Roll Forming Machines

1. High Efficiency One of the primary advantages of C profile roll forming machines is their ability to produce high volumes of profiles in a short amount of time. The continuous nature of the process minimizes downtime and allows for rapid production.

2. Cost-Effectiveness The reduction of material waste and the streamlined production process contribute to lower overall manufacturing costs. Additionally, the automated systems reduce labor expenses and improve consistency in product quality.

3. Precision and Versatility C profile roll forming machines can produce profiles with high precision and uniformity. Factories can easily modify these machines to create different profiles, making them adaptable to changing market demands.

4. Durability and Strength C profiles produced through roll forming are known for their durability, making them suitable for various applications that require long-lasting materials.

Conclusion

C profile roll forming machine factories play a crucial role in the manufacturing industry by providing efficient, precise, and versatile solutions for producing C-shaped profiles. As industries continue to evolve and demand changes, these factories will remain pivotal in meeting the needs of diverse applications. Innovation and technological advancements in roll forming machinery will further enhance production capabilities, supporting the growth of sectors reliant on high-quality metal profiles. Ultimately, the future of C profile roll forming machinery looks promising, with increased automation and customization paving the way for enhanced manufacturing processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025