corrugated sheet rolling machine

Understanding the Corrugated Sheet Rolling Machine A Game Changer in Metal Processing

In the realm of metal processing and manufacturing, the introduction of the corrugated sheet rolling machine has revolutionized the way industries approach sheet metal production. This specialized machinery not only enhances efficiency but also ensures high-quality outputs that meet various industry standards.

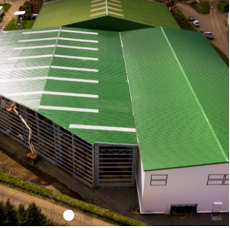

The corrugated sheet rolling machine is designed to produce corrugated sheets from metal, primarily steel and aluminum. These sheets are widely used in a variety of applications, from roofing and wall cladding to packaging and storage units. The unique design of corrugated sheets provides enhanced strength and durability, making them an ideal choice for construction and industrial purposes.

One of the significant advantages of using a corrugated sheet rolling machine is the efficiency it brings to the production process

. Traditional methods of creating corrugated sheets can be labor-intensive and time-consuming, but with the introduction of this machine, manufacturers can significantly increase their output while reducing labor costs. The machine operates continuously, allowing for rapid production of sheets that can be cut to desired lengths and widths, thereby streamlining the entire manufacturing process.corrugated sheet rolling machine

Furthermore, the technology behind these machines has evolved to include advanced features such as Computer Numerical Control (CNC), which allows for precise control over the rolling process. This precision ensures that each sheet produced meets stringent quality standards, reducing waste and minimizing errors. As a result, manufacturers can offer more consistent products, instilling confidence in their customers.

In addition to efficiency and precision, the corrugated sheet rolling machine contributes to sustainability in metal processing. By optimizing the use of raw materials and reducing waste production, manufacturers can lower their environmental impact. Many machines are designed to recycle offcuts and scraps, further enhancing their eco-friendliness.

Moreover, as industries continue to evolve, the demand for customizable corrugated sheets is on the rise. The versatility of corrugated sheet rolling machines allows manufacturers to produce sheets in various sizes, thicknesses, and shapes, catering to the specific needs of their clients. This adaptability helps businesses stay competitive in a dynamic market.

In conclusion, the corrugated sheet rolling machine is an essential asset in modern metal processing. With its ability to increase production efficiency, uphold quality standards, and promote sustainability, it stands as a testament to the innovations that continue to shape the manufacturing landscape. As industries increasingly turn towards these advanced solutions, the future of corrugated sheet production looks promising and poised for growth.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025