corrugated sheet manufacturing machine factory

The Future of Corrugated Sheet Manufacturing Machines

In the ever-evolving landscape of manufacturing, the corrugated sheet industry has carved out a significant niche, thanks in part to the advanced technologies powering modern production machines. Corrugated sheets, known for their lightweight yet durable characteristics, are essential in various applications, including packaging, roofing, and construction. As demand continues to rise, factories specializing in the manufacturing of corrugated sheet machines are not only innovating but also setting the standard for efficiency, sustainability, and quality.

Importance of Corrugated Sheets

Corrugated sheets are characterized by their unique structure of alternating layers, which provide enhanced strength and insulation properties. They are widely used in the packaging industry for shipping boxes, ensuring that products are protected during transit. Additionally, their use in construction as roofing and wall materials is growing, especially in the context of sustainable building practices. With the global push towards eco-friendly materials, corrugated sheets made from recycled paper are quickly gaining traction, driving the need for efficient production machines.

Advanced Manufacturing Technologies

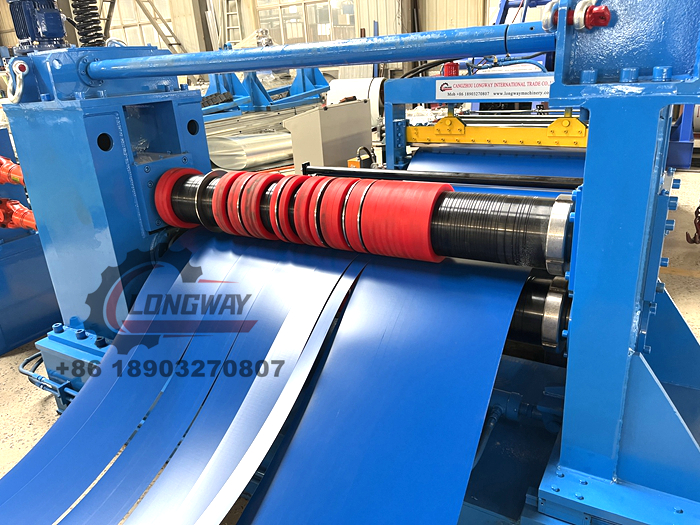

Modern corrugated sheet manufacturing machines incorporate cutting-edge technologies that significantly enhance production capabilities. Automation plays a critical role, with machines equipped with computer numerical control (CNC) systems for precise cutting and shaping. This level of precision reduces waste and ensures consistency across batches, meeting the stringent quality standards demanded by consumers.

Furthermore, many factories are integrating Industry 4.0 principles into their operations. This involves using IoT (Internet of Things) devices to monitor machinery performance in real-time, allowing for predictive maintenance and reducing downtime. Machine learning algorithms can analyze production data to optimize processes, reducing energy consumption and improving output. Such technologies not only streamline operations but also lead to substantial cost savings.

Sustainability Initiatives

corrugated sheet manufacturing machine factory

With environmental concerns at the forefront of many industries, corrugated sheet manufacturing has not been left behind. Factories are increasingly adopting sustainable practices, from sourcing raw materials to minimizing waste. Many production lines now utilize recycled materials, significantly reducing the carbon footprint associated with manufacturing. Additionally, the implementation of eco-friendly manufacturing techniques, such as water-based inks and adhesives, is becoming commonplace.

Moreover, innovations in machine design focus on energy efficiency. Energy-efficient motors and smart energy management systems work together to minimize power consumption, ensuring that the manufacturing process aligns with global sustainability goals. This not only appeals to environmentally conscious consumers but also positions manufacturers favorably in a competitive marketplace.

Investment in Research and Development

To stay at the forefront of the industry, corrugated sheet manufacturing machine factories are investing heavily in research and development. This commitment to innovation ensures that they can respond to emerging trends and consumer demands swiftly. New designs and technologies are continually being explored to enhance the versatility and functionality of corrugated sheets, opening new avenues for product applications.

Collaborations with universities and research institutions have also become a common practice, fostering a culture of innovation. These partnerships allow factories to tap into new materials science developments, leading to stronger, more durable corrugated sheets that meet the needs of various sectors.

Conclusion

The corrugated sheet manufacturing sector stands as a testament to the power of innovation in manufacturing. With advancements in technology, a commitment to sustainability, and continuous investment in research and development, factories specializing in corrugated sheet machines are not only meeting current market demands but are also preparing for the future. As the industry grows, the focus will likely remain on efficiency, sustainability, and adaptability, ensuring that corrugated sheets continue to be a vital resource in our modern economy.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025