Machine for Producing Corrugated Sheets Efficiently and Cost-Effectively

The Role of Corrugated Sheet Manufacturing Machines in Modern Industry

In recent years, the demand for corrugated sheets has surged, driven by the rapid expansion of packaging and construction industries. Corrugated sheets are favored for their lightweight yet durable characteristics, making them ideal for a variety of applications, including roofing, wall cladding, and packaging solutions. At the heart of this production boom is the corrugated sheet manufacturing machine, a cutting-edge technology that has revolutionized the way these essential materials are produced.

Corrugated sheet manufacturing machines are designed to produce sheets from a combination of materials, primarily paperboard or plastic, giving them a corrugated structure that enhances strength and resilience. The manufacturing process is sophisticated and involves several stages, including feeding raw materials, shaping, cutting, and stacking the sheets for further handling. Advanced machines can automate these processes, improving efficiency, reducing waste, and ensuring uniform quality across the production line.

One of the critical components of a corrugated sheet manufacturing machine is the feeder system. This system is responsible for supplying raw materials to the machine. Depending on the design, it can handle different types of paperboard or plastic, ensuring versatility in production. Operators can easily adjust settings to switch between materials or change specifications, allowing for the production of custom sheets as needed.

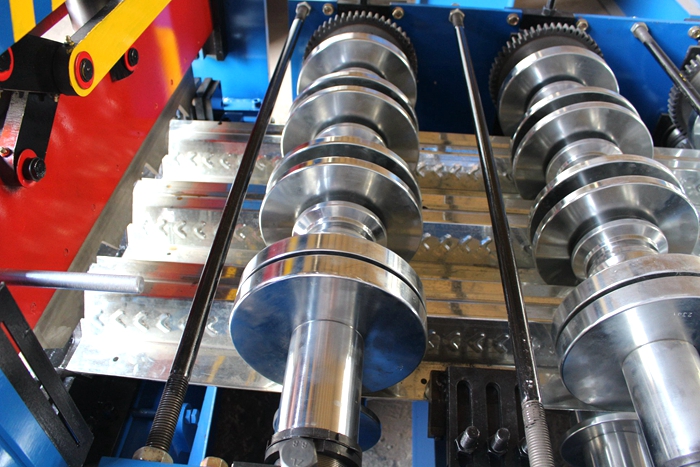

Following the feeding stage, the raw materials are passed through rollers and heated to create the desired corrugated shape. The process also involves adhering layers together using adhesives, which are often engineered for quick drying to enhance production speeds. The precision of the rollers and the uniformity of the heating process are crucial for maintaining the quality of the final product. Modern machines incorporate sensors and computerized controls that ensure consistent pressure and temperature are applied throughout the process.

corrugated sheet manufacturing machine

Cutting is another vital aspect of the manufacturing process. After the sheets have taken their shape, they need to be cut into specific sizes. Advanced corrugated sheet manufacturing machines utilize high-speed cutting mechanisms, often optimized with laser technology or rotary knives, which ensure clean and accurate cuts. This reduces material waste and allows for rapid production cycles, enabling manufacturers to meet the high demands of their customers efficiently.

Once the sheets are cut to size, they are stacked and prepared for shipping. Automated stacking systems are increasingly used in modern manufacturing facilities. These systems help organize the sheets and can even wrap them for protection, further streamlining the process from production to delivery. Automation not only improves efficiency but also reduces the potential for human error, ensuring that each batch of corrugated sheets meets rigorous quality standards.

The environmental impact of corrugated sheet manufacturing is also a crucial consideration. Many manufacturers are now focusing on sustainability, using recycled materials and eco-friendly adhesives. The integration of machines that utilize energy-efficient technologies not only reduces waste but also lowers production costs. Furthermore, as industries shift towards more sustainable practices, the demand for eco-friendly corrugated materials continues to grow.

In conclusion, the evolution of corrugated sheet manufacturing machines reflects the broader trends in modern industry, where efficiency, precision, and sustainability are paramount. As technology continues to advance, we can expect further innovations that will enhance the capabilities of these machines, allowing them to produce even higher-quality products while minimizing their environmental footprint. Companies that invest in state-of-the-art corrugated sheet manufacturing technology are likely to gain a competitive edge in an increasingly demanding market, meeting the needs of diverse industries while promoting a sustainable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025