corrugated sheet making machine manufacturer

The Importance of Corrugated Sheet Making Machines

In today’s fast-paced industrial landscape, the need for efficient and high-quality packaging solutions has never been greater. One of the key components driving this demand is the corrugated sheet making machine. These machines are essential for producing sturdy, lightweight packaging materials that are utilized across various industries, including food and beverage, electronics, and e-commerce.

What is a Corrugated Sheet Making Machine?

At its core, a corrugated sheet making machine is a type of industrial equipment designed to manufacture corrugated sheets from paper. These machines convert flat sheets of paper into a durable product that is characterized by its wavy or fluted shape sandwiched between two flat sheets. This structure provides excellent strength-to-weight ratio, making corrugated sheets the preferred choice for packaging and shipping.

The Manufacturing Process

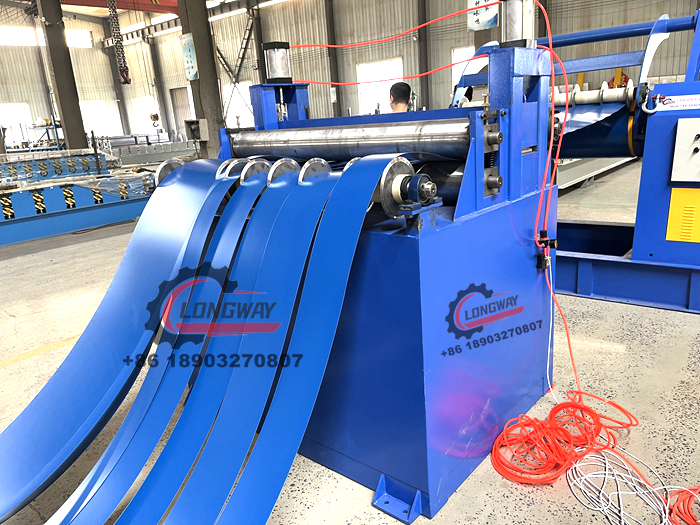

The process of making corrugated sheets involves several steps. Initially, paper rolls are fed into the machine, where they undergo a series of treatments, including heating and pressing. The machine then shapes the paper into a wavy form, which is essential for providing strength and rigidity. Once the fluted paper is prepared, it is glued between two liners, creating a robust corrugated sheet.

Modern corrugated sheet making machines are equipped with advanced technology, allowing for high-speed production and optimal output

. Many manufacturers offer customizable options, allowing businesses to produce sheets in various sizes and thicknesses, catering to the specific needs of their customers.Benefits of Using Corrugated Sheets

corrugated sheet making machine manufacturer

Corrugated sheets come with a plethora of advantages. Firstly, they are lightweight yet strong, making them ideal for transporting goods without adding excessive weight. This feature helps companies save on shipping costs, thereby enhancing overall profitability.

Secondly, corrugated materials are recyclable and eco-friendly. With the increasing focus on sustainability, using recyclable materials is essential for many businesses aiming to reduce their carbon footprint and meet environmental regulations. Corrugated sheets can be reused and recycled multiple times, making them a responsible packaging option.

Additionally, the versatility of corrugated sheets is noteworthy. They can be tailored to specific requirements — from custom sizes and designs to different levels of durability. This adaptability makes them suitable for a wide range of products, including fragile items that require extra protection during transit.

Choosing the Right Manufacturer

When looking to invest in a corrugated sheet making machine, choosing the right manufacturer is crucial. A reputable manufacturer will not only provide high-quality machines but also offer after-sales support and service. It is essential to consider factors such as the machine's production capacity, energy efficiency, and the availability of spare parts.

Working with a trusted manufacturer can also provide access to the latest innovations in corrugated sheet production technology. As the industry evolves, staying updated with advancements can lead to improved efficiency and cost savings.

Conclusion

In summary, corrugated sheet making machines play a vital role in the packaging industry. They facilitate the production of strong, lightweight, and eco-friendly packaging solutions that meet the demands of various sectors. As businesses increasingly focus on sustainability and operational efficiency, the importance of investing in advanced corrugated sheet making machines cannot be overstated. Opting for a reliable manufacturer will ensure that companies can capitalize on the benefits of this indispensable equipment and remain competitive in the marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025