Factory for Manufacturing Corrugated Sheet Production Equipment and Machinery

The Evolution of Corrugated Sheet Making Machine Factories

The demand for corrugated sheets has surged in recent years, driving advancements in the machinery used to produce them. The corrugated sheet making machine factory stands at the forefront of this evolution, embodying innovation, efficiency, and sustainability.

Corrugated sheets are essential in various industries, primarily for packaging, transportation, and construction. Their lightweight yet durable nature makes them ideal for protecting goods during shipping, while their eco-friendly attributes align with the growing emphasis on sustainability. In response to this demand, factories specializing in corrugated sheet making have adopted cutting-edge technologies to enhance production processes.

One of the most significant advancements in corrugated sheet manufacturing is the introduction of automation. Modern factories utilize state-of-the-art automated machines that streamline production, reduce labor costs, and minimize human error. These machines can produce corrugated sheets at unprecedented speeds, ensuring that manufacturers can meet the increasing demands of their clients while maintaining quality standards. Automation not only boosts productivity but also allows for precise control over the manufacturing process, resulting in consistent product quality.

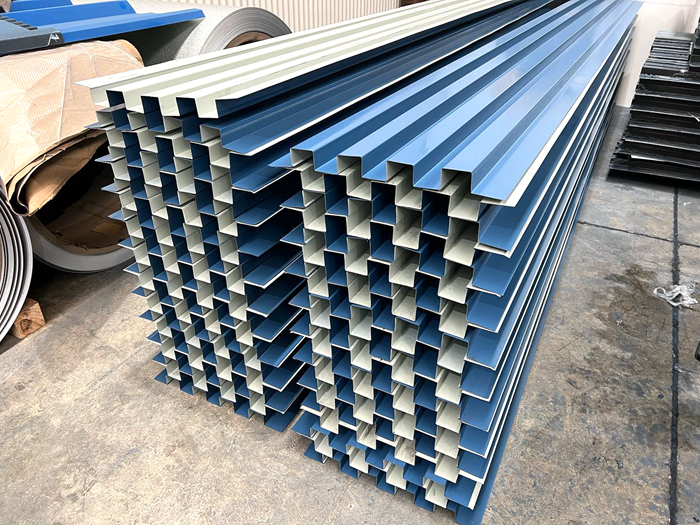

corrugated sheet making machine factory

Energy efficiency is another crucial aspect of corrugated sheet making machine factories. Many manufacturers are now implementing energy-saving technologies to minimize their environmental impact. For instance, newer machines are designed to consume less power while maintaining high output levels. Some factories have even integrated renewable energy sources, such as solar panels, to power their operations, further reducing their carbon footprint.

Moreover, the design of corrugated sheet making machines has evolved to accommodate various materials, including recycled paper. The use of recycled materials not only lowers production costs but also promotes sustainability in the industry. Factories are increasingly sourcing their raw materials from recycled options, aligning with global efforts to reduce waste and promote circular economy practices.

Quality control remains a top priority in corrugated sheet making factories. Advanced inspection systems are now employed to monitor every stage of production, ensuring that the final product meets stringent quality standards. These systems can detect defects in real-time, allowing for immediate corrections and minimizing waste.

In conclusion, corrugated sheet making machine factories are pivotal in meeting the growing demand for versatile and sustainable packaging solutions. With advancements in automation, energy efficiency, and quality control, these factories are not only enhancing productivity but also contributing to a more sustainable future. As the industry continues to evolve, we can expect even greater innovations that will further revolutionize the way corrugated sheets are manufactured.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025