corrugated sheet forming machine manufacturer

The Role of Corrugated Sheet Forming Machine Manufacturers in Modern Industries

In today’s fast-paced industrial landscape, the demand for efficient, high-quality materials is ever-increasing. Among the various materials utilized in construction and packaging, corrugated sheets have emerged as a preferred choice due to their lightweight, durability, and versatility. At the heart of the production of these sheets lies the innovative technology of corrugated sheet forming machines, with manufacturers playing a pivotal role in enhancing capabilities and efficiencies in several industries.

Understanding Corrugated Sheet Forming Machines

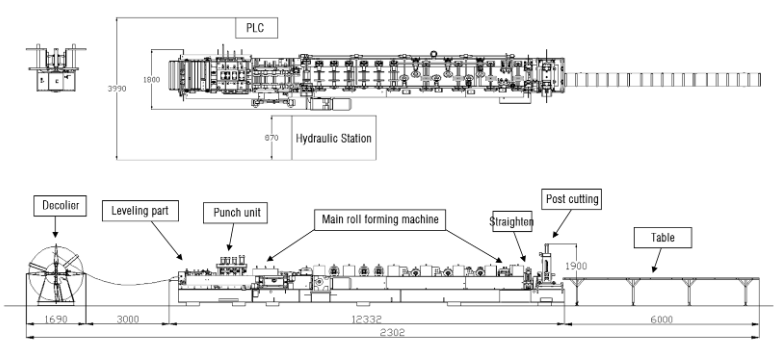

Corrugated sheet forming machines are specialized equipment designed to create corrugated sheets from raw materials, primarily paper or metal. These machines use a series of rollers and other components to process flat sheets, giving them the desired shape and strength through a series of precise transformations. The manufacturing process incorporates cutting, bending, and forming, ultimately resulting in robust sheets ready for various applications, from packaging to architectural uses.

Importance of Quality Manufacturing

The quality and efficiency of corrugated sheet forming machines directly impact the end product. High-quality machines enhance production rates, reduce waste, and maintain consistency in the thickness and strength of the sheets. Manufacturers of these machines are dedicated to employing advanced technologies, such as computer numerical control (CNC) and automation, to ensure precision and reliability. This focus on quality not only benefits the manufacturers but also their clients, who seek durable and cost-effective materials for their projects.

Innovation and Sustainability

corrugated sheet forming machine manufacturer

As industries become increasingly aware of environmental concerns, manufacturers of corrugated sheet forming machines are responding by integrating sustainable practices into their production processes. The rise of eco-friendly materials and the push for reduced carbon footprints have led to the development of machines designed to work with recyclable materials. This innovation not only caters to the growing demand for sustainable solutions but also helps companies comply with environmental regulations.

Additionally, ongoing research and development in manufacturing technology have led to the creation of energy-efficient machines that reduce energy consumption during operation. By minimizing waste and energy use, these advancements contribute to more sustainable production methods.

Custom Solutions for Diverse Industries

One of the standout features of modern corrugated sheet forming machine manufacturers is their ability to offer customized solutions tailored to the specific needs of different industries. Whether it’s the food packaging industry requiring moisture-resistant sheets or the construction sector needing high-strength material, manufacturers work closely with clients to develop machines that meet their unique specifications. This level of customization not only enhances the utility of the machines but also strengthens partnerships between manufacturers and businesses.

Conclusion

In conclusion, corrugated sheet forming machine manufacturers are integral to the advancement of numerous industries that rely on high-quality corrugated sheets. Through a commitment to innovation, sustainability, and customization, these manufacturers not only contribute to the economic growth but also promote environmentally friendly practices in production. As industries continue to evolve, the role of these manufacturers will remain crucial in ensuring that the demand for high-quality, efficient materials is met with cutting-edge technology and sustainable solutions. The future holds immense potential for those involved in the manufacturing of corrugated sheet forming machines, paving the way for a more innovative and environmentally-conscious industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025