corrugated sheet curving machine manufacturer

The Rise of Corrugated Sheet Curving Machines A Manufacturer's Perspective

In recent years, the demand for corrugated sheet curving machines has surged, reflecting the evolving needs of the construction and manufacturing industries. As manufacturers strive to produce aesthetically pleasing and structurally efficient designs, the ability to curve corrugated sheets has become indispensable. This article explores the significance of these machines, the technology behind them, and the key considerations for manufacturers looking to invest in this equipment.

Understanding Corrugated Sheet Curving Machines

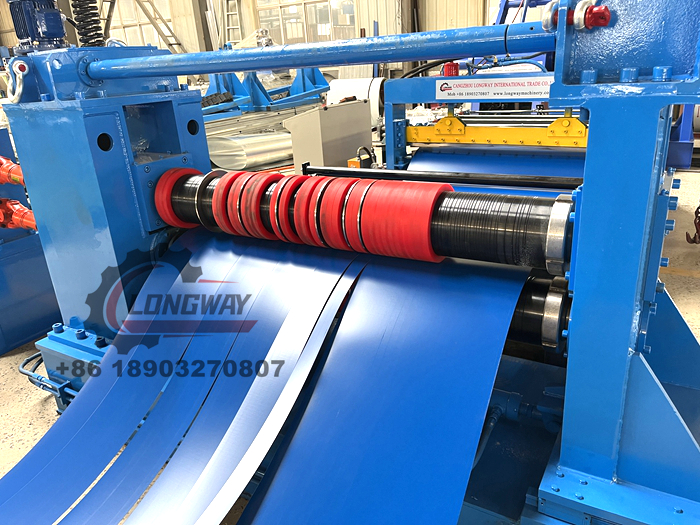

Corrugated sheet curving machines are specialized devices designed to form metal sheets into curved shapes. These machines are essential for creating various architectural and industrial applications, such as roofing, cladding, and decorative elements. The ability to manipulate corrugated sheets into specific curves enables manufacturers to meet custom design requirements, enhancing the versatility and functionality of their products.

What sets these machines apart is their advanced technology, which ensures precision and efficiency in the curving process. Most modern machines utilize a combination of hydraulic mechanisms and computer numerical control (CNC) systems, allowing for highly accurate curves that adhere to specific design specifications. This technological integration not only enhances the quality of the final product but also increases production speed, thereby improving overall operational efficiency.

Applications of Corrugated Sheet Curving Machines

The applications of corrugated sheet curving machines are vast. In the architectural domain, curving metal sheets is essential for creating unique roof designs, canopies, and facades that cater to contemporary aesthetic standards. These machines also play a crucial role in the manufacturing of pre-engineered buildings, where curving is necessary to achieve the desired structural integrity and aesthetic appeal.

In addition to architecture, industries such as automotive, aerospace, and furniture manufacturing have begun to adopt these machines

. The ability to create curved metal components opens up new avenues for design and innovation, enabling manufacturers to produce lightweight, yet strong structures that can withstand various environmental stresses.corrugated sheet curving machine manufacturer

Choosing the Right Manufacturer

For businesses looking to invest in a corrugated sheet curving machine, choosing the right manufacturer is paramount. A reputable manufacturer should not only provide high-quality machines but also offer comprehensive support services, including installation, maintenance, and training. Potential buyers should evaluate manufacturers based on their experience, the technology they utilize, and the feedback from past customers.

Moreover, it is beneficial to consider the flexibility of the machines offered. Manufacturers that provide options for customization, such as different size and power capacities, can better cater to diverse customer needs. Innovations like modular designs or easy retrofitting for future upgrades can also provide a significant advantage in a rapidly evolving market.

Challenges and Future Trends

Despite the advantages corrugated sheet curving machines offer, challenges persist. One notable challenge is the initial capital investment required for advanced machines. However, many manufacturers view this as a long-term investment due to the increased productivity and efficiency these machines can bring.

Looking ahead, continuous advancements in technology are expected to further enhance the capabilities of corrugated sheet curving machines. The integration of artificial intelligence and machine learning could lead to predictive maintenance and smarter operational controls, ultimately transforming how manufacturers approach production processes.

In conclusion, the significance of corrugated sheet curving machines in modern manufacturing cannot be overstated. As industries continue to push for innovative designs and efficient production methods, these machines will play a pivotal role in shaping the future of construction and manufacturing. For manufacturers, adopting the right curving machines symbolizes not only a commitment to quality but also a strategic move towards innovation and adaptability in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025