corrugated roof sheet roll forming machine factory

Understanding Corrugated Roof Sheet Roll Forming Machines A Key Player in Modern Construction

In the ever-evolving construction industry, the demand for durable, efficient, and cost-effective building materials is at an all-time high. One prominent solution that has emerged to meet these needs is the corrugated roof sheet roll forming machine. These machines are essential for producing high-quality corrugated sheets that play a crucial role in roofing applications across various sectors.

What is a Corrugated Roof Sheet Roll Forming Machine?

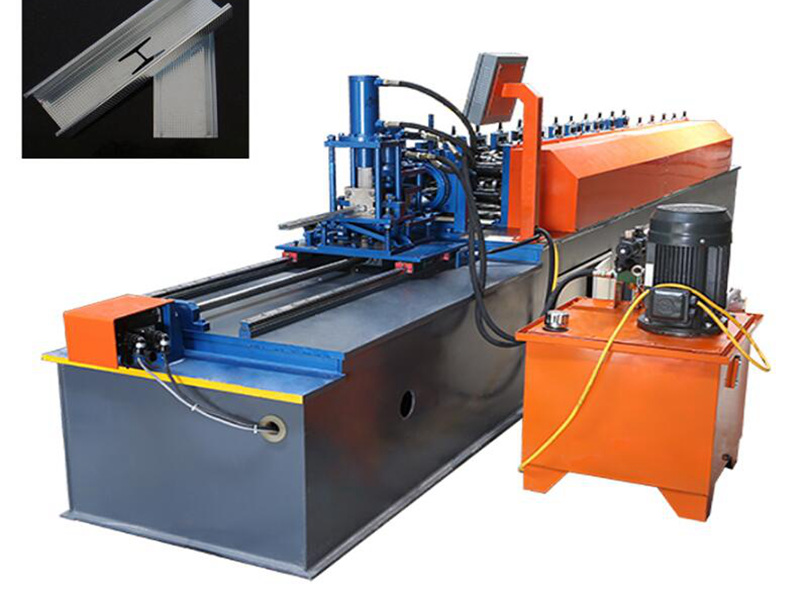

A corrugated roof sheet roll forming machine is a specialized piece of industrial equipment designed to create corrugated sheets from metal strips, typically stainless steel, galvanized steel, or aluminum. The process starts with a coil of metal that is fed through the machine, where it is shaped into a series of ridges and valleys—these geometric features provide strength and rigidity to the sheets. The final product is lightweight, easy to transport, and simple to install, making it ideal for a variety of construction projects.

The Manufacturing Process

The operation of a roll forming machine is a continuous process that consists of several stages. Initially, a metal coil is loaded into the machine. The coil is then uncoiled and straightened to prepare for the forming process. This step is critical to ensure that the metal sheet is uniform and free from any defects.

Following this, the sheet is fed through a series of rollers that gradually form it into the desired shape. Each roller is meticulously designed to create specific profiles at precise angles, producing consistent and accurate corrugation. Once the shaping is complete, the formed sheets can undergo additional processes, such as cutting to specific lengths, applying protective coatings, or even incorporating features like anti-corrosion treatments.

Advantages of Using Roll Formed Corrugated Sheets

1. Durability Corrugated sheets produced by roll forming machines are designed to withstand harsh environmental conditions. Their structural integrity allows them to resist weather impacts, making them suitable for a wide range of climates.

2. Cost-Effectiveness The automated nature of roll forming reduces labor costs and waste significantly. Manufacturers can produce large quantities of sheets in a short period, making it a more economical option than traditional methods.

corrugated roof sheet roll forming machine factory

3. Versatility These sheets can be customized in various sizes, thicknesses, and materials, which makes them applicable for different construction needs—from residential roofs to industrial buildings and agricultural structures.

4. Lightweight and Easy to Install The lightweight nature of corrugated sheets means that they are easy to handle and install. This feature not only reduces the labor required for installation but also minimizes the overall load on the building structure.

5. Aesthetic Appeal Available in a wide range of colors and finishes, corrugated roof sheets can enhance the visual appeal of any structure. This aesthetic versatility makes them a favored choice among architects and designers.

Eco-Friendliness and Sustainability

As sustainability becomes an increasingly important focus in construction, corrugated roof sheet roll forming machines contribute positively to environmental efforts. Metal sheets are recyclable, and the efficient production processes minimize unnecessary waste. Furthermore, many machines are now designed to reduce energy consumption during production, aligning with global eco-friendly initiatives.

Choosing the Right Manufacturer

When selecting a factory to purchase a corrugated roof sheet roll forming machine, it is essential to consider various factors. Look for manufacturers with a proven track record of quality and reliability, as well as those offering comprehensive after-sales support and service. Additionally, assess the technology used in the machinery, as advanced features can enhance efficiency and output quality.

Conclusion

In conclusion, the corrugated roof sheet roll forming machine is a vital component in modern construction. Its ability to efficiently produce strong, versatile, and aesthetically pleasing roofing materials makes it an indispensable tool for builders and manufacturers alike. As construction practices continue to evolve, the role of these machines will undoubtedly remain significant, paving the way for innovative building solutions in the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025