Jan . 14, 2025 09:55

Back to list

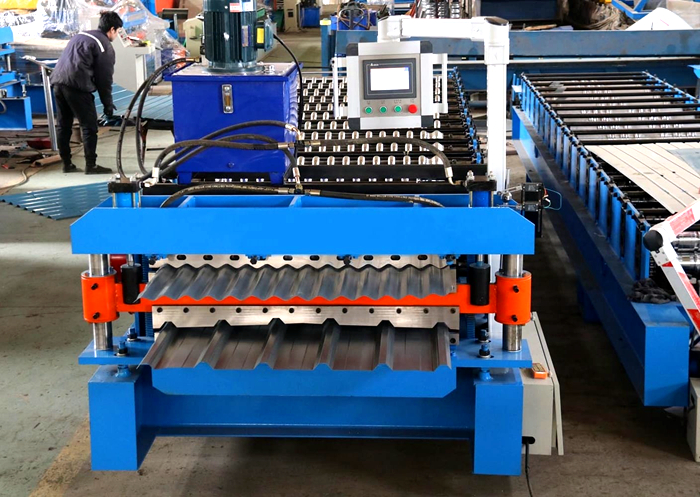

corrugated roof sheet roll forming machine

Exploring the world of corrugated roof sheet roll forming machines provides valuable insights into modern construction and manufacturing efficiency. These machines have become indispensable tools in the production of corrugated metal roofing sheets due to their ability to enhance speed, precision, and consistency in output.

The authority in roll forming technology comes from continuous innovation and adaptation to market demands. Many leading manufacturers are incorporating digital technologies such as IoT and machine learning to optimize machine performance and predictive maintenance. This proactive approach not only extends machine lifecycle but also significantly enhances return on investment by preventing sudden breakdowns. Trustworthiness in choosing the right machine also comes from peer reviews and case studies. Analyzing successful implementations of corrugated roof sheet roll forming machines in similar industry settings can offer practical insights. Moreover, direct consultations with industry professionals can provide guidance tailored to specific operational conditions. Growing environmental concerns have also led to innovations in the roll forming industry. Eco-friendly initiatives are apparent in newer models designed to minimize energy consumption and adhere strictly to environmental standards. Opting for machines that support sustainable practices reflects positively on business ethics and can often align with regulatory requirements, thus avoiding potential compliance issues. To conclude, corrugated roof sheet roll forming machines are at the heart of modern roofing solutions. With the evolving construction landscape, staying abreast of advancements in equipment and technology ensures staying ahead in efficiency, quality, and sustainability. Whether it's about enhancing production lines or developing new project capabilities, investing in a high-quality roll forming machine remains a strategic decision that promises substantial returns both financially and operationally.

The authority in roll forming technology comes from continuous innovation and adaptation to market demands. Many leading manufacturers are incorporating digital technologies such as IoT and machine learning to optimize machine performance and predictive maintenance. This proactive approach not only extends machine lifecycle but also significantly enhances return on investment by preventing sudden breakdowns. Trustworthiness in choosing the right machine also comes from peer reviews and case studies. Analyzing successful implementations of corrugated roof sheet roll forming machines in similar industry settings can offer practical insights. Moreover, direct consultations with industry professionals can provide guidance tailored to specific operational conditions. Growing environmental concerns have also led to innovations in the roll forming industry. Eco-friendly initiatives are apparent in newer models designed to minimize energy consumption and adhere strictly to environmental standards. Opting for machines that support sustainable practices reflects positively on business ethics and can often align with regulatory requirements, thus avoiding potential compliance issues. To conclude, corrugated roof sheet roll forming machines are at the heart of modern roofing solutions. With the evolving construction landscape, staying abreast of advancements in equipment and technology ensures staying ahead in efficiency, quality, and sustainability. Whether it's about enhancing production lines or developing new project capabilities, investing in a high-quality roll forming machine remains a strategic decision that promises substantial returns both financially and operationally.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products