Feb . 16, 2025 03:12

Back to list

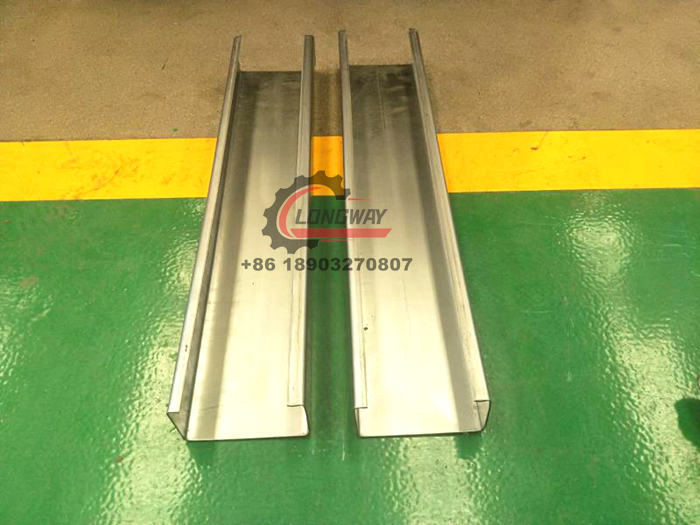

corrugated roof sheet making machine roll forming

In the world of industrial manufacturing and construction, efficiency and precision reign supreme. One of the key players in these sectors is the corrugated roof sheet making machine roll forming line, a sophisticated piece of machinery that transforms raw materials into durable, versatile roofing products. This innovation not only shapes the future of construction but also sets a benchmark in engineering excellence, providing unmatched benefits for manufacturers and consumers alike.

Trustworthiness in this sector is built on a foundation of quality assurance and after-sales service. Each corrugated roof sheet making machine undergoes rigorous testing during and after production to verify that it meets industry standards. Certifications from recognized bodies further attest to a machine’s quality and reliability. In addition, companies offer personalized customer service, helping clients select machines that best suit their production needs. Post-purchase, responsive technical support and maintenance services ensure that the machines operate optimally, minimizing downtime and extending their operational lifespan. Understanding the strategic role of SEO for promoting corrugated roof sheet making machines involves creating content that resonates with potential buyers by answering their critical pain points. For instance, when SEO content focuses on long-term cost savings, manufacturers can discuss how automation reduces labor costs and material waste. This, paired with case studies and success stories, illustrates the tangible benefits of investing in modern roll forming technology. Moreover, leveraging keywords like “efficiency in roofing production,” “customizable roof sheet forming,” and “advanced roll forming technology” within crafted content helps in reaching audiences actively searching for innovative manufacturing solutions online. Content that artfully intertwines these keywords within engaging and informative narratives stands a better chance of improving organic search engine rankings, thereby driving relevant traffic and potential customers to the manufacturer’s website. In conclusion, a corrugated roof sheet making machine roll forming line represents a pivotal advancement in construction manufacturing, built on years of expertise, authority, trust, and innovation. As the demand for sustainable and efficient building materials grows, so too does the importance of this machinery. Its ability to deliver precise, customized products at high speeds positions it as an indispensable tool in the modern manufacturing process, catering to varied market demands with unparalleled reliability.

Trustworthiness in this sector is built on a foundation of quality assurance and after-sales service. Each corrugated roof sheet making machine undergoes rigorous testing during and after production to verify that it meets industry standards. Certifications from recognized bodies further attest to a machine’s quality and reliability. In addition, companies offer personalized customer service, helping clients select machines that best suit their production needs. Post-purchase, responsive technical support and maintenance services ensure that the machines operate optimally, minimizing downtime and extending their operational lifespan. Understanding the strategic role of SEO for promoting corrugated roof sheet making machines involves creating content that resonates with potential buyers by answering their critical pain points. For instance, when SEO content focuses on long-term cost savings, manufacturers can discuss how automation reduces labor costs and material waste. This, paired with case studies and success stories, illustrates the tangible benefits of investing in modern roll forming technology. Moreover, leveraging keywords like “efficiency in roofing production,” “customizable roof sheet forming,” and “advanced roll forming technology” within crafted content helps in reaching audiences actively searching for innovative manufacturing solutions online. Content that artfully intertwines these keywords within engaging and informative narratives stands a better chance of improving organic search engine rankings, thereby driving relevant traffic and potential customers to the manufacturer’s website. In conclusion, a corrugated roof sheet making machine roll forming line represents a pivotal advancement in construction manufacturing, built on years of expertise, authority, trust, and innovation. As the demand for sustainable and efficient building materials grows, so too does the importance of this machinery. Its ability to deliver precise, customized products at high speeds positions it as an indispensable tool in the modern manufacturing process, catering to varied market demands with unparalleled reliability.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products