corrugated roof sheet making machine price factory

The Cost and Value of Corrugated Roof Sheet Making Machines A Comprehensive Overview

In the construction and manufacturing industry, the demand for durable and cost-effective roofing materials is continually rising. Among these materials, corrugated roof sheets stand out for their strength, lightweight properties, and versatility. Consequently, the production of these sheets has seen a surge in demand, leading to the rising prominence of corrugated roof sheet making machines. This article delves into the costs associated with these machines, factors influencing their price, and the overall value they provide to manufacturers.

Understanding Corrugated Roof Sheet Making Machines

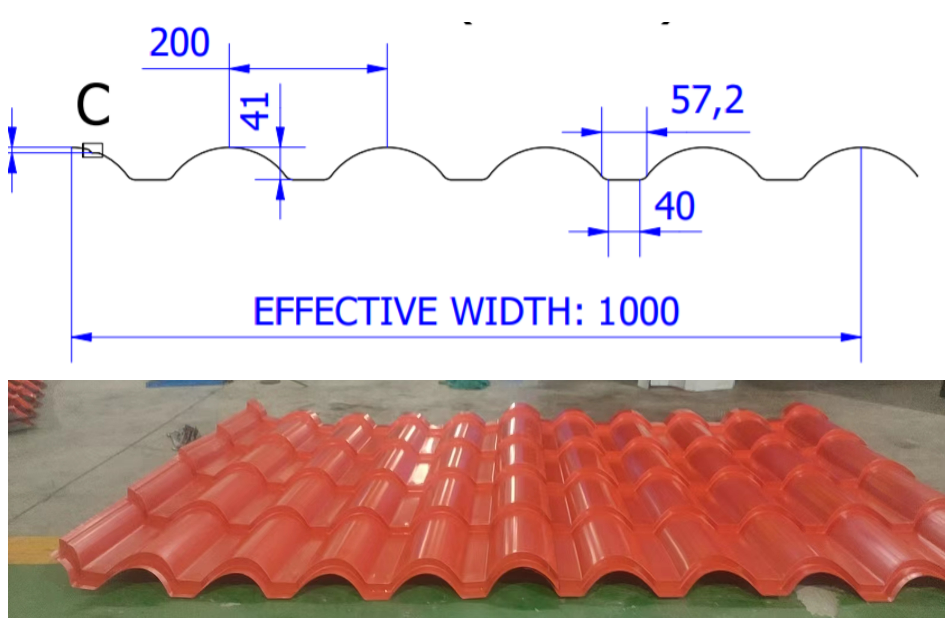

Corrugated roof sheet making machines are specialized equipment designed to produce sheets that are capable of withstanding harsh weather conditions while providing aesthetic appeal. These machines employ various processes, including cutting, forming, and welding, to convert raw materials — typically galvanized steel or aluminum — into finished corrugated sheets. The continuous evolution of technology has led to more efficient and advanced machines that not only improve productivity but also enhance the quality of the final product.

Price Factors

The price of a corrugated roof sheet making machine can vary significantly based on several factors, including

1. Type of Machine Different types of machines are available, from semi-automatic to fully automatic. Fully automatic machines tend to be more expensive but offer higher production rates and reduced labor costs.

2. Production Capacity Machines designed to produce higher quantities of sheets per hour tend to have a higher upfront cost. Buyers must consider their production needs and potential volumes to determine the best machine for their business.

3. Material Used The construction and quality of the machine parts, such as the rollers and cutting tools, can influence the overall price. High-quality materials often lead to improved durability and efficiency, justifying a higher price tag.

4. Brand and Manufacturer Renowned manufacturers often have a premium pricing structure due to their established reputation for quality and reliability. Investing in a machine from a reputable manufacturer may translate to lower maintenance costs and longer machine life.

5. Customization Options Some manufacturers offer customized machines to meet specific production needs. These tailored machines can be more costly than standard models but can provide a better return on investment for certain operations.

corrugated roof sheet making machine price factory

Approximate Pricing

As of 2023, prices for corrugated roof sheet making machines typically range from $10,000 to $100,000 or more, depending on the aforementioned factors. Entry-level machines suitable for small-scale operations can start at around $10,000, while larger, high-capacity, fully automatic systems may exceed $100,000. It’s crucial for potential buyers to conduct thorough market research, considering both their budget constraints and production requirements before making a decision.

Value to Manufacturers

Investing in a corrugated roof sheet making machine offers numerous advantages to manufacturers

1. Cost Efficiency Producing sheets in-house can significantly reduce material costs and overhead in the long run. This savings often outweighs the initial investment in machinery.

2. Quality Control By manufacturing their materials, businesses can maintain strict quality control over the final products. This can enhance customer satisfaction and help establish a reputable brand.

3. Market Flexibility The ability to produce corrugated sheets on-demand allows businesses to respond quickly to market changes and customer demands, providing a competitive edge in the industry.

4. Diversification Opportunities Manufacturers can explore various markets by producing different types of corrugated sheets, thus expanding their product line and increasing revenue potential.

5. Sustainability By controlling the production process, manufacturers can adopt eco-friendly materials and practices, appealing to an increasingly environmentally-conscious market.

Conclusion

The corrugated roof sheet making machine market is rapidly evolving, offering numerous options for manufacturers looking to invest in quality equipment. While the initial cost can be significant, the long-term benefits and potential ROI make these machines a worthwhile investment for many businesses. As the demand for corrugated roofing solutions continues to grow, companies that leverage advanced manufacturing capabilities will be well-positioned to thrive in this competitive landscape. By carefully considering their production needs and conducting thorough research, manufacturers can choose the right machine that fits both their budget and their goals in producing high-quality corrugated roofing materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025