Affordable Corrugated Roof Sheet Manufacturing Machine Prices from Top Suppliers

The Corrugated Roof Sheet Making Machine A Guide to Prices and Companies

In the construction industry, corrugated roof sheets have become increasingly popular due to their durability, lightweight nature, and cost-effectiveness. These sheets have a wide range of applications, from residential buildings to commercial structures. The demand for corrugated roof sheets has led to an uptick in production machinery, specifically the corrugated roof sheet making machine. This article will explore the pricing and key companies involved in the manufacturing of these machines.

Understanding the Corrugated Roof Sheet Making Machine

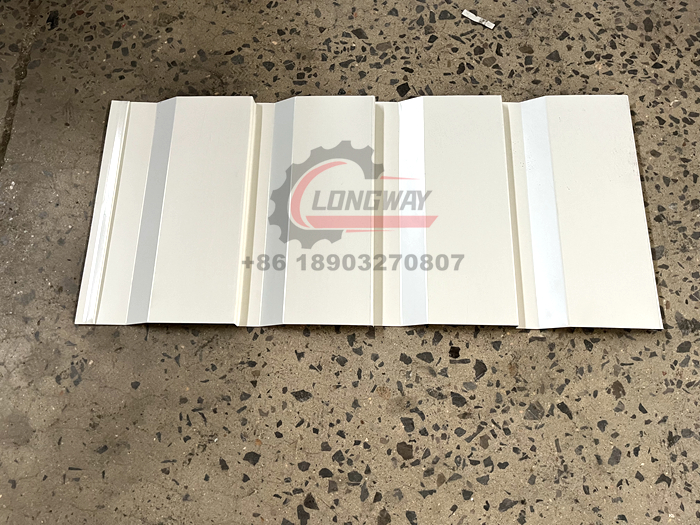

The corrugated roof sheet making machine is designed to produce corrugated sheets from raw materials like galvanized steel, aluminum, or PVC. The machine operates through several stages, including decoiling, feeding, forming, and cutting. The final product is a sturdy, weather-resistant sheet that can withstand various environmental conditions.

Factors Influencing the Prices

The price of the corrugated roof sheet making machine can vary significantly based on several factors

1. Capacity Machines with higher production capacities usually come with a steeper price tag. Companies need to evaluate their production needs and select a machine that balances cost and output.

2. Material Compatibility Machines designed to process different materials might have different prices. For example, a machine that can handle both metal and plastic will generally be more expensive than one that handles only one material.

3. Technology and Features Advanced machines equipped with modern technology features, such as automatic controls, computer-aided design (CAD), and high-speed production capabilities, tend to be priced higher. Buyers looking for efficiency and ease of operation might be willing to invest more in such features.

4. Brand Reputation Established manufacturers with a strong reputation in the market may charge more due to their proven reliability and customer service. However, investing in a reputable brand often translates to better support and longevity of the machinery.

corrugated roof sheet making machine price company

5. Location and Shipping Costs If the machine is sourced internationally, shipping fees and tariffs can significantly affect the overall price. Local manufacturers may provide more cost-effective solutions due to lower transportation costs.

Prominent Companies Manufacturing Corrugated Roof Sheet Making Machines

Several companies have established themselves as key players in the corrugated roof sheet making machine market. Here are a few noteworthy manufacturers

1. Zhongtuo Roll Forming Machine This company is known for producing high-quality roll forming machines, including corrugated roof sheet making machines. Their products are tailored to meet the specific needs of various industries, and they offer comprehensive after-sales support.

2. Foshan Bosheng Machinery Bosheng specializes in advanced machinery for the roofing industry. Their corrugated sheet making machines are well-received in the market, praised for their efficiency and durability.

3. Youdeli Machinery Based out of China, Youdeli is known for its extensive range of sheet metal machinery. They focus on innovative designs and have earned a good reputation for quality and customer service.

4. RoboPlate This company incorporates automation technologies in their machines, enhancing productivity. Their machines offer precision in production, making them popular among businesses aiming for high output.

5. Jiangsu Tanyuan Technology Co., Ltd. Known for offering a wide range of sheet production solutions, Tanyuan Technology boasts several years of experience in the industry. They focus on quality and customer satisfaction.

Conclusion

In conclusion, the corrugated roof sheet making machine is an essential investment for companies looking to capitalize on the growing demand for corrugated roofing solutions. While prices can vary based on various factors, it’s crucial for businesses to assess their needs and choose a machine that offers both quality and efficiency. Partnering with reputed manufacturers not only ensures the purchase of a reliable machine but also guarantees essential support throughout its operational life. As the construction industry continues to evolve, investing in the right machinery will play a significant role in staying competitive and fulfilling market demands.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025