corrugated roof sheet machine

The Evolution and Importance of Corrugated Roof Sheet Machines

In the realm of construction and roofing, the corrugated roof sheet machine plays a pivotal role in shaping the infrastructure of modern buildings. These machines, designed for manufacturing corrugated metal sheets, have evolved significantly over the years. They provide the construction industry with durable, lightweight, and cost-effective materials that can withstand various weather conditions.

Understanding Corrugated Roof Sheets

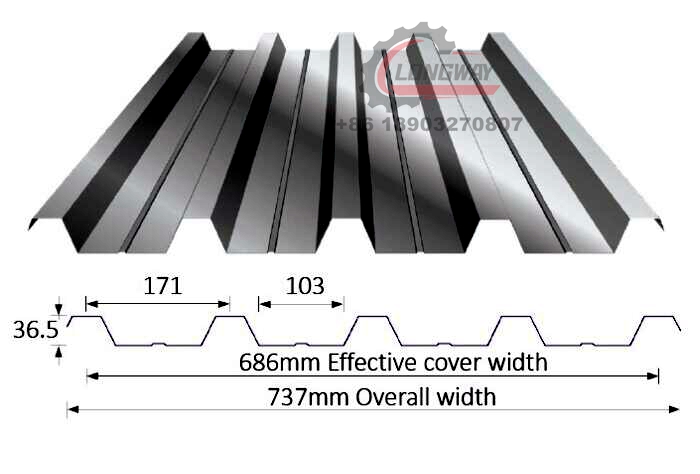

Corrugated roof sheets are made from metal, often galvanized steel or aluminum, and are characterized by their wavy pattern. This design not only enhances the aesthetic appeal of buildings but also adds strength and rigidity to the material. The grooves created during the corrugation process allow the sheets to handle both stress and water drainage effectively, making them ideal for roofing applications.

The Functionality of Corrugated Roof Sheet Machines

Corrugated roof sheet machines are automated systems that streamline the production of these metal sheets. They primarily consist of several key components a metal roll feeder, a forming station, cutting equipment, and stacking mechanisms. The process begins with large coils of metal being fed into the machine, where they undergo a series of rollers that shape them into the desired corrugated pattern. Once formed, the sheets are cut to the required length and stacked for easy handling.

The advancements in technology have revolutionized these machines. Modern corrugated roof sheet machines are equipped with computerized controls, allowing for precise adjustments in parameters such as the depth of corrugation and sheet length. Furthermore, these machines can operate at high speeds, significantly increasing production capacity and reducing labor costs.

Economic and Environmental Benefits

corrugated roof sheet machine

Utilizing corrugated metal sheets produced by these machines offers numerous economic advantages. Their lightweight structure reduces the overall load on building foundations, leading to savings in both materials and installation costs. Additionally, metal roofing is known for its longevity; it can last 50 years or more with minimal maintenance, providing an excellent return on investment.

From an environmental perspective, corrugated metal sheets are often made from recycled materials and are 100% recyclable at the end of their life cycle. This high sustainability factor makes them an attractive option for eco-conscious builders and consumers alike. The energy efficiency of metal roofing also contributes to lower heating and cooling costs for buildings, further solidifying its position as a green building material.

Applications and Versatility

Corrugated roof sheets manufactured by these machines are highly versatile, finding applications in various sectors. They are commonly used for residential homes, commercial buildings, agricultural facilities, and industrial structures. Their ability to be produced in numerous colors and finishes allows for creative design options that cater to aesthetic preferences while ensuring functionality.

In addition to roofing, corrugated sheets can be utilized for wall panels, fencing, and even architectural features, showcasing their adaptability in various construction scenarios. This flexibility, combined with their strength and resistance to harsh weather, ensures that corrugated metal sheets remain a staple in construction projects worldwide.

Future Trends and Innovations

As technology continues to advance, the future of corrugated roof sheet machines appears promising. Innovations such as improved automation, energy-efficient designs, and enhanced software capabilities for better production management are on the horizon. Moreover, the rise of smart manufacturing techniques could lead to more customizable products that meet specific customer demands without compromising quality or efficiency.

In conclusion, the corrugated roof sheet machine is an integral part of modern construction, providing a vital link in the production of durable and efficient roofing materials. Its ability to evolve with technology not only enhances production capabilities but also contributes to economic and environmental sustainability. As we look forward, the continued innovation in these machines will likely propel the construction industry toward even greater heights, ensuring that the buildings of tomorrow are both resilient and resource-efficient.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025