corrugated roof roll forming machine manufacturer

The Rise of Corrugated Roof Roll Forming Machines An Essential Component for Modern Construction

In the evolving landscape of modern construction, the demand for efficient and reliable building materials has never been greater. Among the most significant innovations in this field is the development of corrugated roof roll forming machines. These machines are pivotal in producing corrugated sheets that are widely used for roofing applications, providing enhanced durability, aesthetic appeal, and cost-effectiveness.

Understanding Corrugated Roof Roll Forming Machines

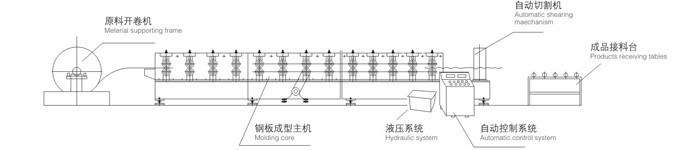

Corrugated roof roll forming machines are specialized equipment designed to manufacture corrugated sheets from various metal materials, including galvanized steel, aluminum, and copper. The process begins with a flat metal coil being fed into the machine, which then systematically passes it through a series of rollers. These rollers shape the metal into specific profiles, creating the characteristic waves or ridges found in corrugated sheets. The result is a lightweight, strong, and weather-resistant product ideal for roofing.

Advantages of Using Corrugated Roof Sheets

The popularity of corrugated roofing can be attributed to several key benefits that these materials offer

1. Durability Corrugated roof sheets are engineered to withstand harsh weather conditions, including heavy rains, strong winds, and snow. Their robust design ensures a long service life, reducing repair and replacement costs over time.

2. Cost-Effectiveness The production process facilitated by roll forming machines is highly efficient, which translates into lower manufacturing costs. Additionally, the lightweight nature of corrugated sheets reduces transportation and installation expenses.

corrugated roof roll forming machine manufacturer

3. Versatility These roof sheets are available in various materials, colors, and thicknesses, making them suitable for a wide range of applications, from residential homes to large industrial structures. Their adaptability allows architects and builders to achieve specific design goals.

4. Energy Efficiency Some corrugated roofing materials come with reflective coatings that enhance energy efficiency by reducing heat absorption. This is particularly beneficial in warmer climates, as it helps maintain a comfortable indoor environment.

The Role of Manufacturers

Manufacturers of corrugated roof roll forming machines play a crucial role in advancing the production capabilities of roofing materials. By utilizing the latest technology, these companies are able to enhance machine performance, improve product quality, and increase production speed. Modern machines often come equipped with advanced features such as programmable controls, allowing for precise adjustments to meet specific customer requirements.

Moreover, environmental sustainability is becoming a central focus for many manufacturers. This includes not only the use of recyclable materials but also the implementation of energy-efficient processes within the manufacturing operations. By prioritizing sustainability, manufacturers contribute to the broader goal of reducing the carbon footprint associated with construction.

Conclusion

As the construction industry continues to evolve, the importance of quality materials and efficient production processes cannot be overstated. Corrugated roof roll forming machines are essential tools that empower manufacturers to produce high-quality roofing sheets that meet the diverse needs of the market. With their numerous advantages, including durability, cost-effectiveness, and versatility, corrugated roof sheets are an ideal choice for builders and homeowners alike.

Investing in a reliable corrugated roof roll forming machine is not merely a business decision but a step towards embracing innovation and sustainability in the construction sector. As we look towards the future, it is clear that these machines will play a pivotal role in shaping the roofs of tomorrow, ensuring that they are not only functional but also aesthetically pleasing and environmentally friendly.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025