Top Manufacturers of Machines for Producing Corrugated Roofing Sheets

The Rising Demand for Corrugated Roofing Sheet Making Machines

In recent years, the construction industry has witnessed a significant transformation, primarily due to the increasing demand for durable and efficient building materials. Among these, corrugated roofing sheets have gained remarkable popularity due to their cost-effectiveness, lightweight properties, and exceptional durability. To meet this growing demand, manufacturers of corrugated roofing sheet making machines are at the forefront of innovation, providing essential machinery that helps produce high-quality roofing sheets.

Understanding Corrugated Roofing Sheets

Corrugated roofing sheets are made from various materials, including metal, plastic, and fiberglass, and are characterized by their distinctive wavy or ridged pattern. This design not only enhances aesthetic appeal but also offers structural benefits by providing strength and rigidity. Their resistance to harsh weather conditions, coupled with low maintenance needs, makes them an ideal choice for both residential and commercial buildings.

Importance of Machinery in Production

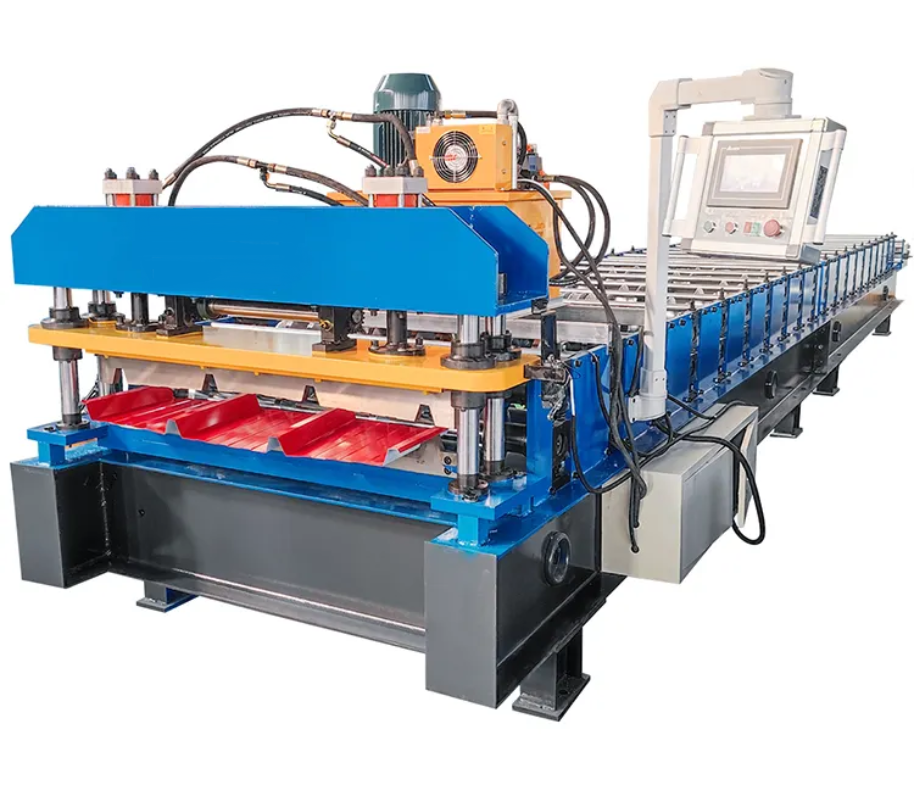

The process of manufacturing corrugated roofing sheets requires specialized machinery that ensures precision, efficiency, and high output. Manufacturers of corrugated roofing sheet making machines put great emphasis on technological advancements to enhance production capabilities. These machines typically involve processes such as roll forming, cutting, and shaping materials into the desired corrugated form.

Modern machines have incorporated automation and advanced control systems, allowing for better quality control and reducing waste. Additionally, advancements in materials science mean that manufacturing machines can now handle a wider variety of raw materials, thereby expanding the range of products that can be offered.

Key Features of Corrugated Roofing Sheet Making Machines

1. High Efficiency and Speed Today's machines are designed to operate at high speeds, significantly increasing productivity. This efficiency is vital for meeting market demands and ensuring profitability.

2. Versatility Manufacturers often seek machines that can produce various profiles and thicknesses of corrugated sheets, enabling them to cater to diverse customer needs.

3. User-Friendly Controls With the integration of digital interfaces and automation, operators can easily manage production settings, monitor outputs, and quickly adjust to changes in demand.

corrugated roofing sheet making machine manufacturers

4. Durability and Reliability High-quality machines are built to withstand prolonged use, minimizing downtime and maintenance costs. This is crucial for manufacturers who rely on steady production rates.

5. Energy Efficiency As sustainability becomes more pressing, efficient energy use in manufacturing processes has become a priority. Many modern machines incorporate energy-saving features that help reduce operational costs.

The Role of Manufacturers

The role of manufacturers in providing corrugated roofing sheet making machines is crucial. They not only design and produce machines but also offer after-sales services, technical support, and training for operators. This comprehensive support ensures that companies investing in such machinery can maximize their capabilities and maintain consistent production quality.

Moreover, with the rise of digital marketing and global trade, manufacturers are now reaching wider markets. Companies across different continents are exploring partnerships with machine manufacturers, allowing for diverse business opportunities and collaborations.

Future Trends

As urbanization continues to grow, the demand for affordable and reliable roofing solutions, such as corrugated sheets, will likely increase. This trend presents a significant opportunity for manufacturers of corrugated roofing sheet making machines. Innovations in manufacturing processes, such as the use of artificial intelligence and machine learning, will likely drive efficiency even further.

Additionally, the focus on sustainability may lead to the development of eco-friendly materials and production techniques. Manufacturers that adapt to these changes can not only thrive but also contribute positively to the environment.

Conclusion

The demand for corrugated roofing sheet making machines is set to rise as construction materials evolve to meet modern standards of durability, efficiency, and sustainability. Manufacturers play a critical role in this industry, leveraging technology to produce machines that empower businesses to meet market demands. As the industry continues to grow, staying ahead of trends and innovations will be essential for manufacturers to remain competitive and successful. Thus, investing in high-quality corrugated roofing sheet making machines is a strategic move for companies looking to thrive in this dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025