Manufacturer of Corrugated Roofing Sheet Production Equipment and Solutions

The Advancements in Corrugated Roofing Sheet Making Machines

In the construction and manufacturing industry, the demand for durable and lightweight materials continues to rise. One of the most effective solutions for roofing requirements is corrugated roofing sheets. The production of these sheets is facilitated by advanced machinery, leading to an increase in efficiency, productivity, and overall quality. This article explores the significance of corrugated roofing sheet making machines and the companies that specialize in their manufacturing.

Understanding Corrugated Roofing Sheets

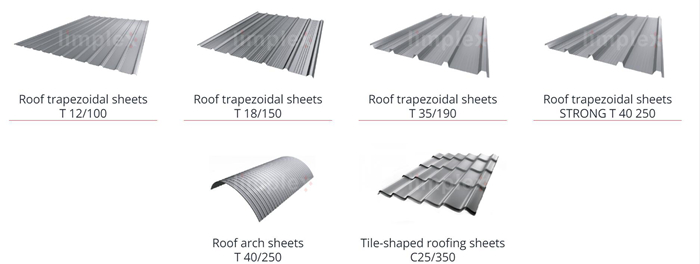

Corrugated roofing sheets are known for their unique design, characterized by alternating ridges and grooves. This structure enhances their strength and resilience against various weather conditions. Made from materials such as metal, plastic, and fiberglass, these sheets are widely used in building construction, agricultural structures, and industrial facilities. They are favored for their lightweight nature, ease of installation, and cost-effectiveness.

The Role of Machinery in Production

The production of corrugated roofing sheets involves several stages, including material preparation, shaping, cutting, and finishing. A corrugated roofing sheet making machine automates these processes, significantly reducing labor costs and minimizing errors. These machines can handle a variety of raw materials, allowing manufacturers to diversify their product offerings.

The latest machinery incorporates advanced technology, including computer numerical control (CNC) systems, which ensure precision in designing and forming the sheets. Additionally, these machines are built to accommodate different thicknesses and types of materials, making them versatile for various applications.

Key Features of Modern Machines

Modern corrugated roofing sheet making machines come equipped with a range of features that improve functionality and efficiency

. Some of these include1. High Production Speed Advanced machines can produce a large number of sheets per hour, meeting the increasing demand in the construction sector. 2. Energy Efficiency Operating on efficient motors and mechanisms, these machines consume less power than older models, making them more environmentally friendly.

corrugated roofing sheet making machine company

3. User-Friendly Controls With intuitive interfaces, operators can easily manage the machine's functions, ensuring a smoother production process.

4. Durability and Maintenance Built from high-quality materials, these machines are designed for longevity and require minimal maintenance, providing manufacturers with a reliable production line.

5. Customization Options Many companies offer customizable machines that can be tailored to specific production needs, whether it is for different sizes, patterns, or materials of roofing sheets.

Leading Companies in the Industry

Numerous companies specialize in the manufacture and supply of corrugated roofing sheet making machines. These companies are known for their innovation, quality, and customer service. Leading firms focus on research and development to integrate the latest technology into their machines.

1. Zhongtuo Machinery Known for its state-of-the-art designs, Zhongtuo offers a range of roofing sheet making machines that support various materials and sizes.

2. KMR Group This company is recognized for its robust machinery capable of producing high-quality corrugated sheets, with a focus on energy-efficient operations.

3. Siddhivinayak Engineering With years of experience, Siddhivinayak specializes in customized solutions, allowing customers to produce sheets tailored to specific market demands.

Conclusion

The corrugated roofing sheet making machine industry is rapidly evolving, driven by technological advancements and the ever-increasing demand for high-quality materials in construction. As companies continue to innovate, the future of corrugated roofing sheets looks promising, providing enhanced durability, efficiency, and sustainability. For manufacturers looking to succeed in this competitive market, investing in modern machinery is paramount, ushering in a new era of productivity and quality in roofing solutions. These advancements not only benefit producers but also contribute to more sustainable construction practices worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025