corrugated roofing sheet forming machine factories

The Evolution and Importance of Corrugated Roofing Sheet Forming Machines

In the construction industry, the materials used play a significant role in determining the durability, aesthetic appeal, and overall effectiveness of structures. Among these materials, corrugated roofing sheets have gained popularity due to their unique design and functional advantages. The production of these sheets relies heavily on advanced technology, particularly through the use of corrugated roofing sheet forming machines. This article explores the evolution, operation, and significance of these machines in contemporary manufacturing processes.

Evolution of Corrugated Roofing Sheets

Corrugated roofing has a rich history, dating back to the mid-19th century when it was first introduced in the United States. Initially made from metal and employed primarily for agricultural buildings, corrugated sheets have since evolved in terms of materials and applications. Today, these sheets are manufactured using steel, aluminum, and even plastic composites. They offer several benefits, such as lightweight, ease of installation, and resistance to harsh weather conditions.

With the growing demand for corrugated roofing sheets in both residential and commercial applications, the need for efficient and reliable production methods became apparent. This led to the development of specialized machines designed to form these sheets with precision and consistency.

The Functionality of Corrugated Roofing Sheet Forming Machines

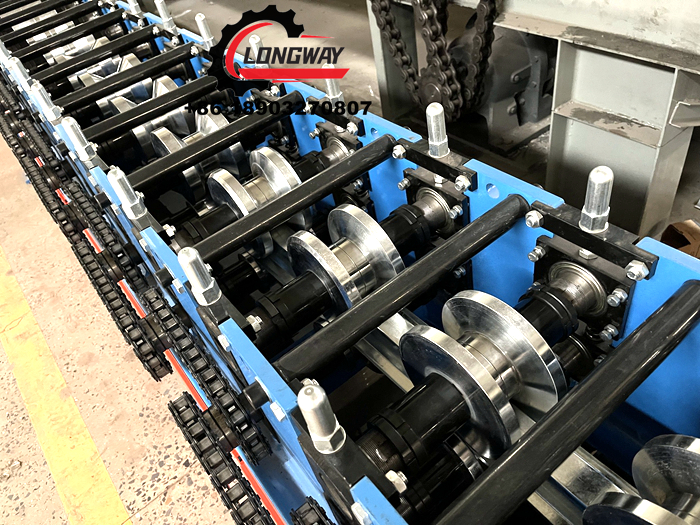

At the heart of manufacturing corrugated roofing sheets are the forming machines, which have undergone significant advancements over the years. These machines are designed to convert raw materials into finished products through a series of processes that include cutting, bending, and shaping.

1. Material Feeding The process begins with feeding long coils of sheet metal or other materials into the forming machine. Advanced machines are equipped with automatic feeding systems to streamline the operation and reduce manual labor.

2. Roll Forming The core of the machine consists of a series of rollers arranged in a specific configuration. As the material passes through these rollers, it is gradually shaped into the desired corrugated profile.

3. Cutting Once the material has been formed into sheets, the machine cuts them into specified lengths. This ensures uniformity and meets the requirements of various construction projects.

corrugated roofing sheet forming machine factories

Advantages of Modern Forming Machines

The modern corrugated roofing sheet forming machines come equipped with various features that enhance productivity and efficiency. Some notable advantages include

- Automation With advanced technology, many machines offer automated operations, reducing the need for manual intervention. This not only speeds up production but also minimizes the risk of human errors.

- Customization Manufacturers can produce sheets with varying widths, heights, and profiles, catering to specific customer needs. This flexibility is crucial for meeting diverse market demands.

- Energy Efficiency Many contemporary machines are designed to operate efficiently, consuming less energy while maximizing output. This not only reduces operational costs but also supports eco-friendly manufacturing practices.

- Quality Control Advanced monitoring systems and sensors ensure that the formed sheets meet quality standards. This is vital for maintaining the integrity of the sheets, as any defects can lead to significant issues in construction.

Importance in the Construction Industry

The significance of corrugated roofing sheet forming machines transcends mere production. They play a crucial role in the construction industry's supply chain, ensuring that quality materials are readily available for various applications. The lightweight nature of corrugated sheets makes them ideal for roofing in both residential and commercial buildings, while their durability ensures long-term performance.

Moreover, with the increased emphasis on sustainable building practices, corrugated sheets serve as an appealing option. Their recyclability and efficiency in resource use position them as a responsible choice for modern construction endeavors.

Conclusion

In conclusion, the evolution of corrugated roofing sheet forming machines is a testament to the advancements in manufacturing technology. These machines not only enhance production efficiency but also contribute significantly to the construction industry's sustainability and quality standards. As we continue to build towards the future, the role of these machines becomes ever more critical in shaping our skylines and protecting our structures.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025