Manufacturing Equipment for Corrugated Roofing Sheet Roll Forming Solutions

The Evolution and Importance of Corrugated Roofing Roll Forming Machines

In the realm of construction and architecture, the choice of roofing materials plays a critical role in determining a building's longevity, aesthetic appeal, and energy efficiency. Among the various options available, corrugated roofing has emerged as a popular choice due to its unique combination of durability, cost-effectiveness, and versatility. At the heart of this innovation lies the corrugated roofing roll forming machine, a vital piece of equipment for manufacturers aiming to produce high-quality roofing sheets at scale.

Understanding Corrugated Roofing

Corrugated roofing consists of sheets that are shaped in a series of parallel ridges and valleys. This design not only enhances structural strength but also allows for efficient drainage of rainwater, reducing the risk of leaks and water damage. Furthermore, corrugated sheets are available in various materials, including metal, plastic, and fiberglass, allowing them to cater to a wide array of building requirements. The lightweight nature of these materials, combined with their robust structural integrity, makes them ideal for both residential and commercial applications.

The Role of Roll Forming Machines

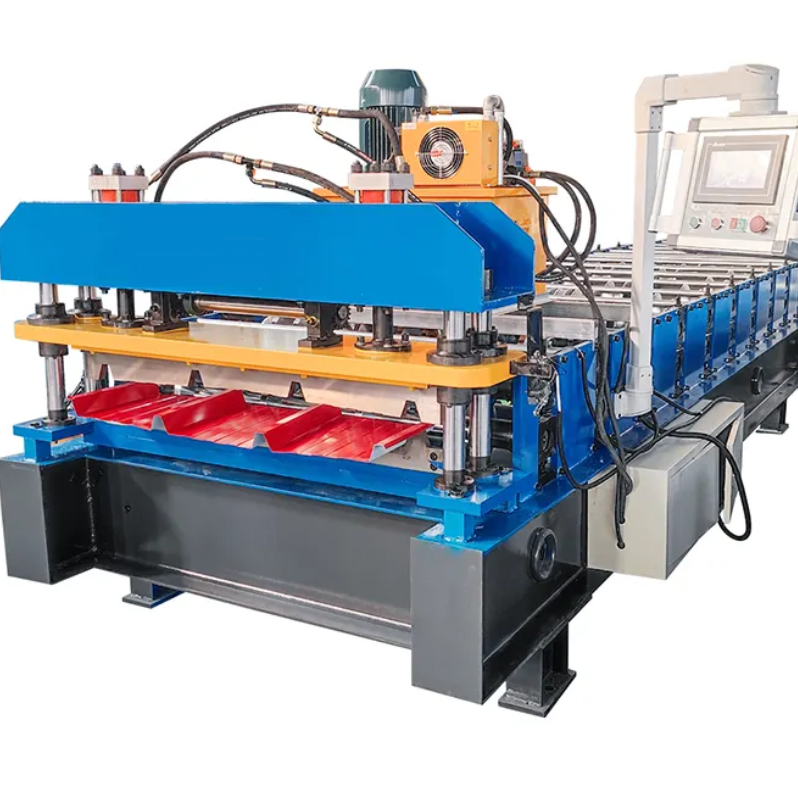

A corrugated roofing roll forming machine automates the production of corrugated sheets through a highly efficient process. The process begins with flat metal coils being fed into the machine, which then gradually shapes the metal into corrugated profiles through a series of rollers. This method ensures consistency in product quality and reduces manual labor, leading to higher productivity rates.

These machines can be customized to produce varying widths and thicknesses of roofing sheets, making them invaluable to manufacturers. The ability to adjust specifications means that producers can meet diverse client demands and adapt to market trends. Moreover, modern roll forming machines come equipped with advanced digital controls, enabling precision and reducing waste, thereby enhancing cost-efficiency.

Advantages of Corrugated Roofing Roll Forming Machines

corrugated roofing roll forming machine factory

1. High Production Speed The automation provided by roll forming machines significantly speeds up the manufacturing process, allowing businesses to meet high-volume orders efficiently. This is paramount in a competitive market where time is of the essence.

2. Consistent Quality Automated processes yield uniform products, minimizing variations and ensuring that every sheet meets set quality standards. This results in fewer defects, which is crucial for maintaining the reputation of manufacturing businesses.

3. Flexibility With adjustable settings, manufacturers can quickly switch between different profiles and sizes, catering to custom orders or changing market demands without extensive downtime.

4. Cost-Effectiveness By reducing labor costs and raw material waste through precision engineering, roll forming machines present a more economical solution for producing corrugated roofing materials.

5. Sustainability Many manufacturers are now employing environmentally friendly practices by utilizing recycled materials. Advanced roll forming technology allows for minimal waste during production, aligning with sustainable business practices.

Conclusion

The corrugated roofing roll forming machine is not merely a piece of equipment; it represents a significant advancement in manufacturing technology that has transformed the roofing industry. By offering speed, efficiency, and flexibility, these machines empower manufacturers to meet the ever-evolving demands of the market while maintaining high-quality standards. As construction continues to evolve, the importance of such machines will only increase, paving the way for innovative materials and techniques in the quest for more efficient and sustainable building solutions.

In summary, the corrugated roofing roll forming machine stands at the forefront of a revolution in roofing materials, providing the essential backbone for the production of one of the most versatile and durable roofing solutions available today.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025