Factories Manufacturing Corrugated Roofing Machines for Durable Construction Solutions

The Evolution and Importance of Corrugated Roofing Machine Factories

In recent years, the construction industry has witnessed significant advancements, particularly in the field of roofing solutions. Among these innovations, corrugated roofing has emerged as a preferred choice due to its durability, affordability, and aesthetic appeal. At the heart of this revolution are corrugated roofing machine factories, which play a crucial role in the manufacturing process of these essential building materials.

What Are Corrugated Roofing Machines?

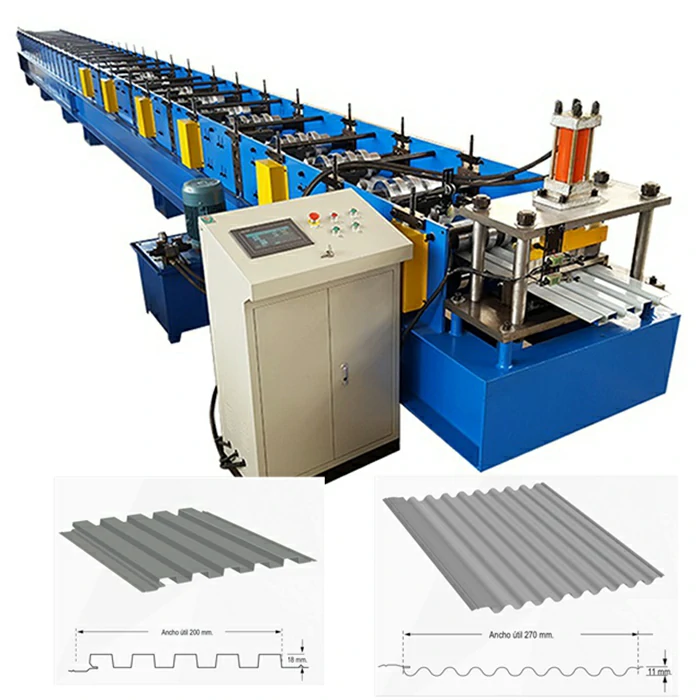

Corrugated roofing machines are specialized equipment designed to produce corrugated sheets from various materials, primarily metal and plastic. These machines are capable of transforming flat sheets into wavy or ridged panels through a process known as roll forming. The result is a lightweight yet sturdy roofing solution that can withstand harsh environmental conditions, making it ideal for residential, commercial, and industrial applications.

The Role of Factories in Production

Corrugated roofing machine factories are pivotal in ensuring the continuous supply of high-quality corrugated sheets. These facilities are equipped with advanced machinery and technology that enhance efficiency, reduce waste, and maintain consistent product quality. The factories often employ skilled workers who are trained to operate the machines effectively, ensuring that production runs smoothly and adheres to safety standards.

Moreover, these factories often serve multiple markets. They produce a variety of corrugated sheet profiles, catering to different architectural styles and customer preferences. Whether it's classic galvanized steel roofing for barns or colorful PVC sheets for urban warehouses, these factories are adept at meeting diverse client needs.

The Manufacturing Process

The manufacturing process in these factories typically involves several stages. Initially, raw materials such as metal coils or plastic sheets are loaded into the machines. The roll forming process then shapes the sheets into corrugated forms. After forming, the products are cut to the desired lengths and undergo quality checks. Additional processes, such as painting or galvanizing, may be applied to enhance the corrosion resistance and aesthetic appeal of the sheets.

corrugated roofing machine factories

Quality control is a critical aspect of the production process. Factories implement strict testing protocols to ensure that the sheets meet industry standards for strength, thickness, and weather resistance. This commitment to quality helps establish a strong reputation in the market and fosters long-term customer relationships.

Economic Impact

The presence of corrugated roofing machine factories significantly contributes to local economies. By creating jobs and fostering skills development, these factories help stimulate economic growth in their regions. Furthermore, they support local supply chains by sourcing materials and services from nearby providers.

As global demand for sustainable construction materials increases, many corrugated roofing machine factories are adopting eco-friendly practices. By utilizing recyclable materials and minimizing waste, these factories not only reduce their environmental impact but also appeal to a growing base of environmentally conscious consumers.

Future Trends

Looking ahead, the future of corrugated roofing machine factories appears promising. Innovations in technology, such as automation and AI-driven production lines, are likely to enhance efficiency further. Additionally, as the trend towards sustainable building practices continues to grow, factories may invest in developing roofing materials that offer improved energy efficiency and eco-friendliness.

Moreover, manufacturers are exploring new materials and designs to meet the changing needs of the market. The rise of modular and prefabricated construction techniques is likely to influence the design and production of corrugated roofing sheets, providing new opportunities for innovation.

Conclusion

Corrugated roofing machine factories are essential players in the construction industry, driving the production of a versatile and reliable roofing solution. As these facilities evolve and adapt to changing market demands, they will undoubtedly continue to play a vital role in shaping the future of building materials. With their contributions to economic growth, innovation, and sustainability, corrugated roofing machine factories are not just manufacturing units; they are crucial components of a modern and resilient construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025