Corrugated Roofing Machine Manufacturer for Efficient and Durable Solutions for Your Projects

The Role of Corrugated Roofing Machine Companies in Modern Construction

In today's fast-paced construction industry, efficiency, durability, and cost-effectiveness are paramount. Among the key players facilitating these aspects are corrugated roofing machine companies. These specialized manufacturers create the machines that produce corrugated metal sheets, a popular roofing material known for its strength and longevity.

What is Corrugated Roofing?

Corrugated roofing refers to sheets of metal that have been shaped into a series of parallel ridges and valleys—creating a wave pattern. This design not only enhances the aesthetic appeal of buildings but also provides superior strength and rigidity. These sheets are typically made from materials like steel, aluminum, or galvanized iron, making them resistant to extreme weather conditions, corrosion, and impact damage.

Importance of Corrugated Roofing Machine Companies

Corrugated roofing machine companies play a critical role in the construction supply chain. They manufacture and supply specialized machinery that allows for the efficient production of corrugated sheets. These machines can vary greatly in complexity, from simple roll-forming equipment to fully automated systems that integrate cutting, bending, and stamping processes.

1. Innovation in Manufacturing These companies often lead the charge in technological advancements. Their machines are designed with cutting-edge technology that increases production speeds and reduces waste. Features such as computer numerical control (CNC) machining and automation enable precise shaping and cutting, allowing manufacturers to produce high-quality roofing sheets consistently.

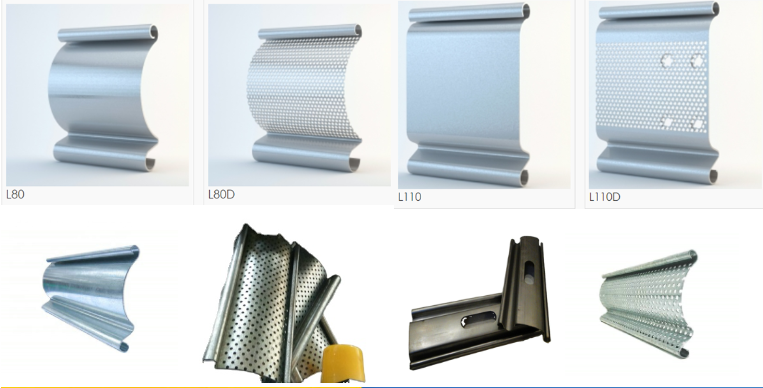

2. Customization and Versatility Different construction projects require different specifications. Corrugated roofing machine companies provide customizable solutions to meet diverse needs. For example, they can manufacture machines that produce a variety of sheet profiles and dimensions. This versatility allows roofing contractors to cater to both residential and commercial projects, adapting to unique designs and requirements.

corrugated roofing machine company

3. Economic Efficiency The advent of advanced corrugated roofing machines has resulted in significant economic benefits. By producing sheets in-house, construction companies can lower their material costs and reduce lead times. This not only saves money but also allows for greater flexibility in timelines—critical in an industry where delays can be costly.

4. Sustainability Many corrugated roofing machine manufacturers are also focusing on sustainability. With a growing emphasis on eco-friendly construction practices, these companies are developing machines that minimize energy consumption and material waste. Additionally, a range of sustainable materials, such as recycled steel, can be utilized in the manufacturing process, further enhancing the green credentials of corrugated roofing systems.

5. Global Reach and Accessibility Corrugated roofing machine technology has gained international traction, with numerous companies exporting their machines worldwide. This global outreach allows construction businesses in various regions to access high-quality equipment, thereby promoting the widespread adoption of corrugated roofing solutions. As construction expands in emerging markets, the demand for efficient and reliable roofing solutions continues to grow, further benefiting machine manufacturers.

Future Outlook

As urbanization accelerates and the demand for innovative building solutions increases, the corrugated roofing industry stands poised for growth. Corrugated roofing machine companies are likely to continue evolving, integrating artificial intelligence and machine learning to enhance production processes even further. With advancements in robotics and automation, future machines could become more efficient and cost-effective, solidifying corrugated roofing’s place as a preferred option in the construction industry.

Conclusion

In conclusion, the contributions of corrugated roofing machine companies are invaluable to the construction sector. Their innovations in manufacturing technology not only support the production of high-quality roofing materials but also empower builders to adapt to a rapidly changing market. As the construction landscape continues to evolve, these companies will undoubtedly play a vital role in shaping the future of roofing solutions, demonstrating that efficiency and sustainability can go hand in hand.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025