Cost of Corrugated Roll Forming Machines in Today's Market

Understanding the Price Factors of Corrugated Roll Forming Machines

In the realm of manufacturing and construction, efficiency and cost-effectiveness are paramount. One of the cornerstones of efficient metal fabrication is the roll forming process, particularly when it comes to producing corrugated sheets. A corrugated roll forming machine is an essential piece of equipment used to create these sheets, which can be used in various applications, including roofing, siding, and other structural elements. However, the price of these machines can vary significantly based on numerous factors.

What is a Corrugated Roll Forming Machine?

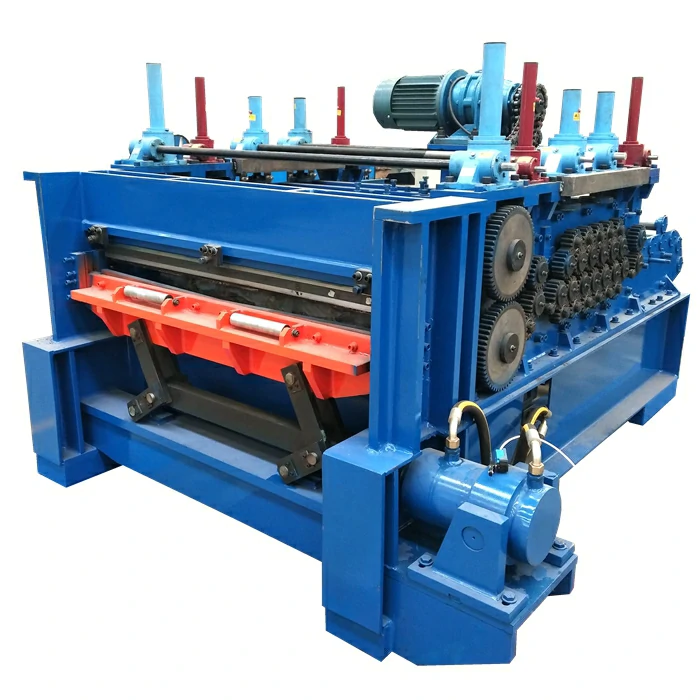

A corrugated roll forming machine is specially designed to produce corrugated metal sheets. The process involves feeding a coil of metal, typically steel or aluminum, through a series of rollers that progressively shape the material into the desired corrugated profile. The end product is lightweight, durable, and offers excellent structural integrity, making it a popular choice in the construction industry.

Key Factors Influencing Price

1. Machine Specifications The price of a corrugated roll forming machine can vary based on specifications such as the production speed, the thickness of the material it can handle, and its overall capacity. Higher specifications usually translate to a higher price due to the advanced technology and sturdier materials used in the construction of the machine.

2. Type of Machine There are various types of corrugated roll forming machines, including single layer and double layer machines. Single layer machines are typically less expensive but offer less flexibility compared to double layer machines, which can manufacture multiple profiles. The choice of machine directly impacts the cost; hence, understanding the specific needs of your production is vital in making a cost-effective purchase.

3. Automation Level Modern machines come with differing levels of automation. Fully automated machines, which require less manual intervention, tend to be more expensive. However, they increase productivity and reduce labor costs in the long run, making them a worthwhile investment for larger operations.

corrugated roll forming machine price

4. Material Quality The quality of the materials used in manufacturing the machine itself can also affect the price. Machines made from high-grade steel with superior components will naturally command a higher price. Investing in a durable and reliable machine can save costs on maintenance and repairs over time.

5. Market Demand The price of corrugated roll forming machines is also subject to market demand. In periods of high demand for construction materials, prices can rise due to increased competition among buyers. Conversely, during economic downturns, prices may drop as demand decreases.

6. Manufacturer Reputation Well-established manufacturers with a reputation for quality and reliability may charge a premium for their machines. However, purchasing from a reputable company often comes with the benefit of better customer support, warranties, and a more durable product, which can justify the higher initial investment.

7. Custom Features If a buyer requires custom features or modifications on the machine, this can increase the overall price. Customization could include adjustments for specific types of corrugation, enhanced safety features, or integrated technology for better efficiency.

Average Price Range

While the cost of corrugated roll forming machines varies widely, prices typically range from $10,000 to over $100,000. For smaller-scale operations, entry-level machines might be available on the lower end of the spectrum. In contrast, large-scale producers seeking high-speed, automated solutions may need to invest significantly more.

Conclusion

Investing in a corrugated roll forming machine is a critical decision for any manufacturing or construction business. Understanding the various factors that influence pricing can help potential buyers make informed choices that align with their production needs and budgets. Ultimately, it’s essential to strike a balance between quality, functionality, and cost, ensuring that the investment supports the business's long-term goals and efficiency. By carefully considering these aspects, companies can optimize their operations and enhance their competitive edge in the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025