Factories for Production of Corrugated Iron Sheet Making Machines

The Rise of Corrugated Iron Sheet Making Machines A Boon for the Construction Industry

In recent decades, the construction industry has witnessed significant advancements in material technology, particularly with the introduction of corrugated iron sheets. These sheets, known for their strength, durability, and versatility, have become an essential component in various building projects worldwide. The rise of corrugated iron sheet making machines has revolutionized how these materials are produced, executed, and implemented across different industries.

Understanding Corrugated Iron Sheets

Corrugated iron sheets are made from thin steel plates that are shaped into a series of parallel ridges and valleys. This design provides inherent strength and rigidity, making them ideal for roofing and cladding applications. The sheets are typically coated with protective materials to prevent corrosion, thereby extending their lifespan and reducing maintenance costs. Due to their lightweight nature, corrugated iron sheets are easily transported and installed, making them a popular choice for both residential and commercial construction projects.

The Role of Corrugated Iron Sheet Making Machines

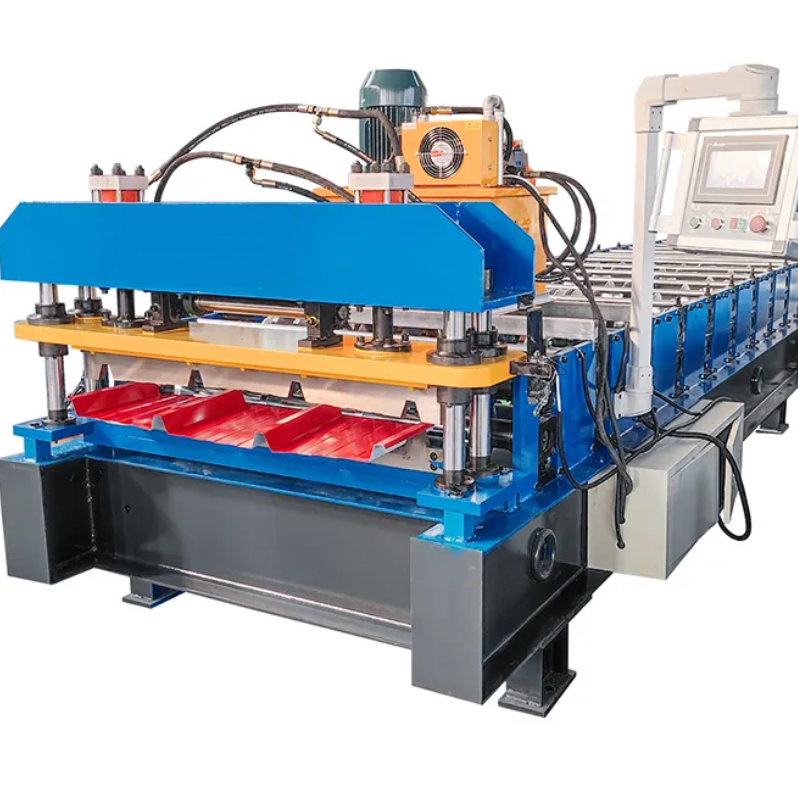

The introduction of advanced corrugated iron sheet making machines has streamlined the production process, enabling factories to meet the rising demand for these materials. These machines come equipped with state-of-the-art technology, allowing for high-speed and efficient production. They are designed to transform metal coils into precisely shaped corrugated sheets with minimal labor and maximum output.

The manufacturing process begins with the feeding of steel coils into the machine, which then cuts and forms the sheets according to specific specifications. Many modern machines are computer-controlled, ensuring high precision and consistency across all produced sheets. Moreover, manufacturers can easily customize the sheets based on thickness, width, and length, catering to various client needs.

Advantages of Automated Production

corrugated iron sheet making machine factories

The automation of corrugated iron sheet production offers numerous advantages. First, it significantly reduces labor costs and the potential for human error, which can lead to waste and inefficiency. Factories can operate continuously, maximizing output and ensuring that they can meet demand even during peak construction seasons.

Additionally, automated machines are often designed with energy efficiency in mind. They consume less power than older models, resulting in lower operating costs and a reduced carbon footprint. Manufacturers are increasingly adopting eco-friendly practices, thereby contributing to sustainability efforts in the construction industry.

Growing Demand and Global Market Trends

The global market for corrugated iron sheets is expanding rapidly, driven by urbanization and infrastructure development in emerging economies. Countries in Asia, Africa, and Latin America are experiencing a construction boom, creating a robust demand for affordable, durable building materials. As a result, the need for efficient corrugated iron sheet making machines is on the rise.

Factory owners are investing in these machines not just for production efficiency, but also to maintain competitive pricing in a growing market. The ability to customize products and adapt to market trends is critical in securing contracts for large-scale projects, making these machines an invaluable asset.

Conclusion

In summary, the emergence of corrugated iron sheet making machines has transformed the production landscape for one of the most widely used construction materials. With advanced technology enhancing efficiency and customization, factories are well-equipped to meet the growing demand in the construction industry. As urbanization continues to rise and sustainable practices gain traction, the role of these machines will only become more pivotal. The future of construction looks promising, with corrugated iron sheets playing a central role in shaping the buildings and infrastructure of tomorrow. As manufacturers embrace this technology, they are not only improving their production capabilities but also contributing to the broader goals of sustainability and economic growth in the construction sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025