Jan . 31, 2025 01:19

Back to list

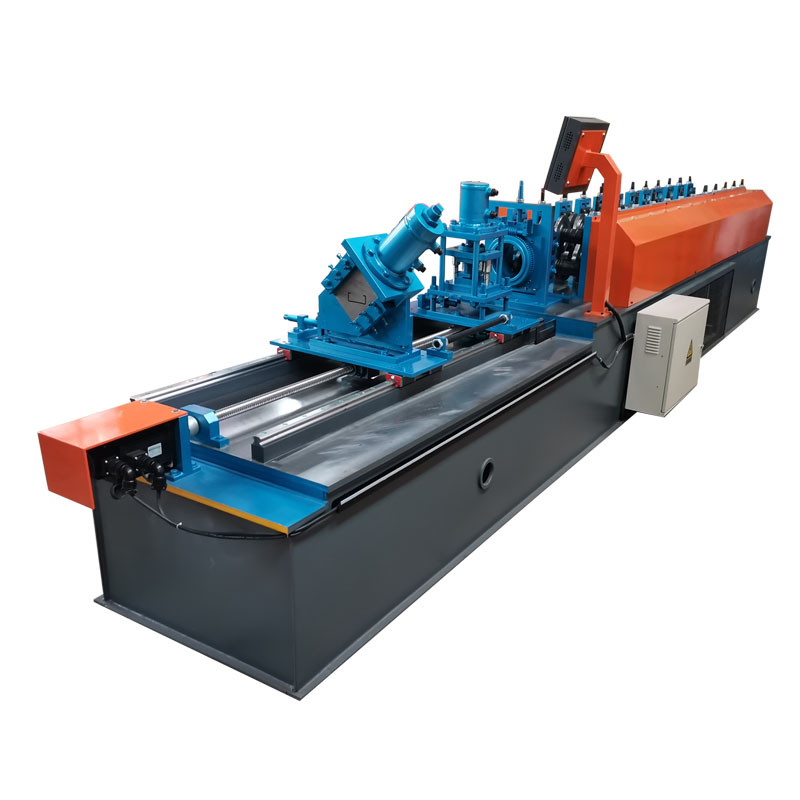

corrugated iron sheet making machine

The corrugated iron sheet making machine has revolutionized the construction industry, providing an efficient and cost-effective solution for producing durable, weather-resistant roofing and siding materials. This article will delve into the essential features of this machinery, the technical expertise required to operate it, and its significant impact on the industry, positioning it as a vital component for both large-scale and small-scale construction projects.

The authoritative presence of corrugated iron sheet making machines in construction is underscored by their widespread application across various sectors. From industrial buildings to agricultural installations and urban infrastructure, the versatility of corrugated sheets is unmatched. Their lightweight nature combined with durability makes them an excellent choice for swift installations, reducing overall construction timelines and labor costs. Additionally, these sheets are eco-friendly, as they can be recycled, aligning with global sustainability goals. Thus, the machine not only supports economic efficiencies but also contributes positively to environmental conservation efforts. Building trust in the machinery's capabilities comes from recognizing the proven track record and reliability that these machines have demonstrated over decades. Manufacturers adhere to strict quality assurance protocols, often subjecting their products to rigorous testing under different environmental conditions. This commitment to quality is accompanied by comprehensive after-sales support, providing training and resources to enable users to maximize the utility of their machines. Installation support, technical assistance, and access to spare parts ensure that investment in a corrugated iron sheet making machine is sound and secure. In conclusion, the corrugated iron sheet making machine is a cornerstone of modern construction technology, embodying the fusion of engineering expertise, technological innovation, and practical application. Its role in the production of essential building materials affirms its value, making it indispensable for construction professionals worldwide. As the industry continues to evolve, these machines will undoubtedly remain at the forefront, supporting sustainable development and architectural advancement.

The authoritative presence of corrugated iron sheet making machines in construction is underscored by their widespread application across various sectors. From industrial buildings to agricultural installations and urban infrastructure, the versatility of corrugated sheets is unmatched. Their lightweight nature combined with durability makes them an excellent choice for swift installations, reducing overall construction timelines and labor costs. Additionally, these sheets are eco-friendly, as they can be recycled, aligning with global sustainability goals. Thus, the machine not only supports economic efficiencies but also contributes positively to environmental conservation efforts. Building trust in the machinery's capabilities comes from recognizing the proven track record and reliability that these machines have demonstrated over decades. Manufacturers adhere to strict quality assurance protocols, often subjecting their products to rigorous testing under different environmental conditions. This commitment to quality is accompanied by comprehensive after-sales support, providing training and resources to enable users to maximize the utility of their machines. Installation support, technical assistance, and access to spare parts ensure that investment in a corrugated iron sheet making machine is sound and secure. In conclusion, the corrugated iron sheet making machine is a cornerstone of modern construction technology, embodying the fusion of engineering expertise, technological innovation, and practical application. Its role in the production of essential building materials affirms its value, making it indispensable for construction professionals worldwide. As the industry continues to evolve, these machines will undoubtedly remain at the forefront, supporting sustainable development and architectural advancement.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products