corrugated iron roofing sheet making machine price manufacturer

Understanding the Pricing and Manufacturing of Corrugated Iron Roofing Sheet Making Machines

Corrugated iron roofing sheets have long been favored in the construction industry due to their durability, resistance to weather conditions, and cost-effectiveness. With the increasing demand for these sheets in various sectors, the need for efficient and reliable corrugated iron roofing sheet making machines has risen significantly. This article explores the factors influencing the price of these machines, the manufacturing process, and what potential buyers should consider.

The Importance of Corrugated Iron Roofing Sheets

Before delving into the machinery, it’s essential to understand why corrugated iron roofing sheets are so popular. These sheets, made of galvanized iron, are lightweight yet robust, making them ideal for residential, commercial, and industrial buildings. They provide excellent protection from rain, wind, and extreme temperatures. Additionally, their corrugated design offers enhanced strength and rigidity, which helps in safeguarding structures against environmental challenges.

Manufacturing Process of Roofing Sheets

The production of corrugated iron roofing sheets involves several key stages

1. Raw Material Selection The primary material used is galvanized steel, which undergoes a coating process to enhance its resistance against rust and corrosion.

2. Sheet Formation The raw steel is rolled into thin sheets, which are then fed into a forming machine. This machine bends the sheets into a corrugated shape, a process that adds to the structural integrity of the final product.

3. Cutting and Finishing After the sheets are formed, they are cut to the specified lengths. Various finishing processes, including painting or coating, may be applied to improve aesthetics and provide additional protection.

corrugated iron roofing sheet making machine price manufacturer

Factors Affecting the Price of Corrugated Iron Roofing Sheet Making Machines

The price of corrugated iron roofing sheet making machines can vary significantly, influenced by several factors

1. Technology and Features Advanced machines equipped with cutting-edge technology usually come at a higher price. Features such as automated controls, higher production capacity, and improved energy efficiency can all impact the overall cost.

2. Production Capacity Machines designed for high output will generally be more expensive. Buyers need to consider their production needs when evaluating options, as investing in a higher-capacity machine could lead to long-term cost savings.

3. Brand and Manufacturer Reputation Renowned manufacturers with a proven track record often charge a premium for their machines. While the initial investment may be higher, these machines might offer better reliability and after-sales support.

4. Location and Market Conditions The price may also vary against different geographical backdrops. Import duties, transportation costs, and local demand can influence the final price of the machines.

5. Customization Options Some manufacturers offer bespoke machines tailored to specific requirements. Customization can affect the price, adding to the machine's versatility and utility.

Making an Informed Purchase Decision

When looking to purchase a corrugated iron roofing sheet making machine, potential buyers should consider their production volume, budget, and potential return on investment. It's crucial to assess the technological features that align with their operational needs. Additionally, conducting thorough research and seeking quotes from multiple manufacturers can help ensure a competitive price.

In conclusion, understanding the corrugated iron roofing sheet making machine market is essential for prospective buyers. By considering the factors outlined, they can make informed decisions that suit their manufacturing needs while optimizing costs. With the right machine, businesses can enhance productivity, meet market demand, and ultimately contribute to the growing construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

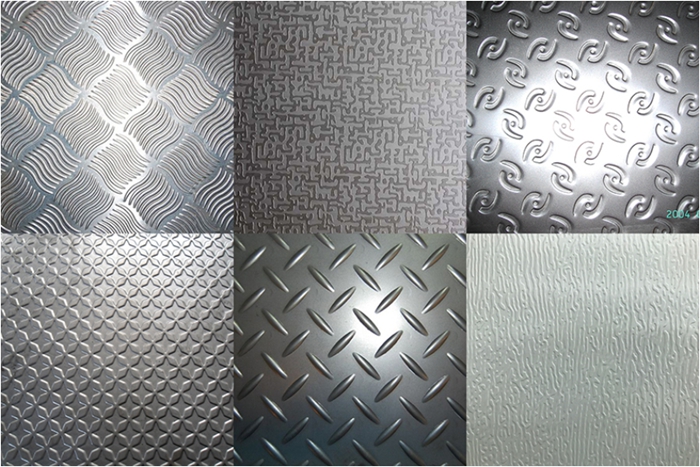

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025