corrugated iron roofing sheet making machine price factory

The Price of Corrugated Iron Roofing Sheet Making Machines A Comprehensive Overview

In the modern construction industry, the demand for durable and reliable roofing materials has led to the increasing popularity of corrugated iron roofing sheets. These sheets are favored for their strength, lightweight nature, and affordability. As a result, the market for corrugated iron roofing sheet making machines has grown. This article explores the various factors that influence the prices of these machines, their manufacturing process, and the emerging trends in the industry.

Understanding Corrugated Iron Roofing Sheets

Before delving into the machinery aspect, it is essential to understand why corrugated iron sheets are such a popular choice in roofing. Their unique corrugated design provides enhanced structural integrity, making them resistant to strong winds, heavy rain, and snow loads. Additionally, they are incredibly low-maintenance and can last for decades when properly installed. These advantages make corrugated iron sheets a preferred option for residential, commercial, and industrial buildings.

The Role of Machinery in Production

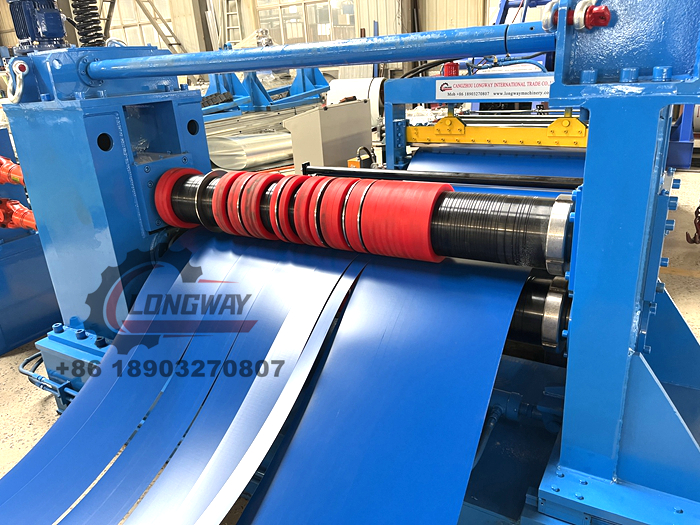

The production of corrugated iron sheets requires specialized machinery that can efficiently convert raw materials into finished products. Corrugated iron roofing sheet making machines come with various features, including roll forming technology, cutting tools, and stacking systems. The initial investment in these machines can significantly impact the overall production efficiency and cost-effectiveness of manufacturing businesses.

Factors Influencing Prices

corrugated iron roofing sheet making machine price factory

1. Machine Specifications The price of a corrugated iron roofing sheet making machine can vary widely based on its specifications, including production capacity, automation level, and the quality of materials used in construction. More advanced machines that offer higher production speeds and lower labor requirements typically come with a higher price tag.

2. Manufacturer Reputation Established manufacturers often charge more for their machines due to brand reliability and after-sales service. Investing in machines from reputable manufacturers can provide long-term benefits in terms of performance and maintenance.

3. Location and Shipping Costs The location of the factory also plays a significant role in pricing. Machines manufactured in regions with higher operational costs or those that require significant shipping across borders may be priced higher.

4. Market Demand Fluctuating market demands for corrugated iron sheets can affect machine prices. An increase in construction activity often leads to higher demand for manufacturing equipment, ultimately driving up prices.

Future Trends

The future of corrugated iron roofing sheet production appears promising, with growing innovations in machine technology aimed at enhancing efficiency and lowering production costs. Additionally, environmental considerations are leading to the development of greener manufacturing practices, which may influence machinery design and pricing.

In conclusion, investing in a corrugated iron roofing sheet making machine is a significant decision influenced by various factors. Understanding these factors can help potential buyers make informed choices and optimize their investment in the roofing industry. As the demand for efficient and reliable roofing materials persists, the market for these machines will continue to evolve, offering new opportunities for manufacturers everywhere.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025