Jan . 26, 2025 07:55

Back to list

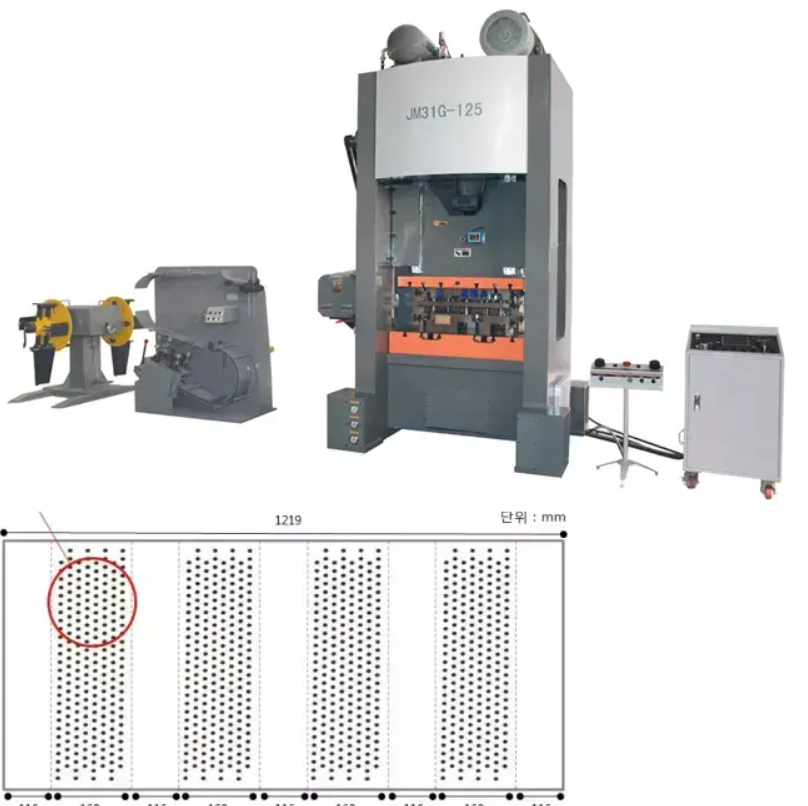

Two deck roll forming machine for micro calamina ondulada

Investing in a corrugated iron roofing sheet making machine can be a pivotal decision for businesses in construction and manufacturing sectors. As the demand for durable roofing solutions rises globally, understanding the intricacies of these machines and their pricing becomes essential.

Technological Advancements and Innovations Technological progress in machinery and manufacturing cannot be overlooked. Modern machines often integrate cutting-edge technologies such as IoT for diagnostics and predictive maintenance. While these features may increase the initial investment, the resultant efficiency gains and reduced long-term maintenance costs present a compelling business case. Market Dynamics and Vendor Credibility Price fluctuations in the corrugated iron roofing sheet making machine market are also influenced by vendor reputation and geographical market demands. Established manufacturers with a history of reliability and industry acclaim typically offer machines at a premium. However, these vendors provide peace of mind with robust warranties and exceptional customer service, factors that significantly contribute to trust and reliability. Parallelly, import tariffs and logistical costs play a role in the final purchase price, especially when acquiring from international manufacturers known for their technological prowess. Budgetary Considerations and Return on Investment (ROI) While evaluating such an investment, it is vital to balance affordability against anticipated ROI. Small to medium enterprises might consider entry-level models that provide core functionalities without excessive financial strain. Conversely, larger enterprises with higher throughput requirements may prefer advanced machines with superior capabilities to maximize productivity and long-term gains. Companies must conduct a careful cost-benefit analysis, considering total cost of ownership rather than just the purchase price. Operational costs, energy efficiency, and maintenance expenses should be factored into the decision-making process. In conclusion, a profound understanding of these factors not only guides businesses in making an informed purchasing decision but also provides a pathway to achieving sustainable profitability. By investing in the right corrugated iron roofing sheet making machine, businesses can ensure they remain competitive, efficient, and poised for future growth in the construction industry.

Technological Advancements and Innovations Technological progress in machinery and manufacturing cannot be overlooked. Modern machines often integrate cutting-edge technologies such as IoT for diagnostics and predictive maintenance. While these features may increase the initial investment, the resultant efficiency gains and reduced long-term maintenance costs present a compelling business case. Market Dynamics and Vendor Credibility Price fluctuations in the corrugated iron roofing sheet making machine market are also influenced by vendor reputation and geographical market demands. Established manufacturers with a history of reliability and industry acclaim typically offer machines at a premium. However, these vendors provide peace of mind with robust warranties and exceptional customer service, factors that significantly contribute to trust and reliability. Parallelly, import tariffs and logistical costs play a role in the final purchase price, especially when acquiring from international manufacturers known for their technological prowess. Budgetary Considerations and Return on Investment (ROI) While evaluating such an investment, it is vital to balance affordability against anticipated ROI. Small to medium enterprises might consider entry-level models that provide core functionalities without excessive financial strain. Conversely, larger enterprises with higher throughput requirements may prefer advanced machines with superior capabilities to maximize productivity and long-term gains. Companies must conduct a careful cost-benefit analysis, considering total cost of ownership rather than just the purchase price. Operational costs, energy efficiency, and maintenance expenses should be factored into the decision-making process. In conclusion, a profound understanding of these factors not only guides businesses in making an informed purchasing decision but also provides a pathway to achieving sustainable profitability. By investing in the right corrugated iron roofing sheet making machine, businesses can ensure they remain competitive, efficient, and poised for future growth in the construction industry.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products