Manufacturer of Machines for Curving Corrugated Metal Sheets Efficiently and Accurately

The Importance of Corrugated Iron Curving Machines Transforming Metalwork Industry

In the modern construction and roofing sectors, the demand for specialized machinery has grown exponentially. One such essential piece of equipment is the corrugated iron curving machine. Manufacturers of these machines play a crucial role in facilitating the production of aesthetically pleasing and structurally sound structures. This article outlines the significance, functionalities, and benefits of corrugated iron curving machines, and provides insights into what to look for when choosing a manufacturer.

Understanding Corrugated Iron Curving Machines

Corrugated iron has been a staple material in construction, particularly for roofs and wall cladding due to its durability and lightweight properties. However, the innovation of curving corrugated iron presents opportunities for enhanced designs and architectural creativity. Curved iron provides unique aesthetic and functional benefits, from improving the flow of rainwater to enhancing the overall appearance of buildings.

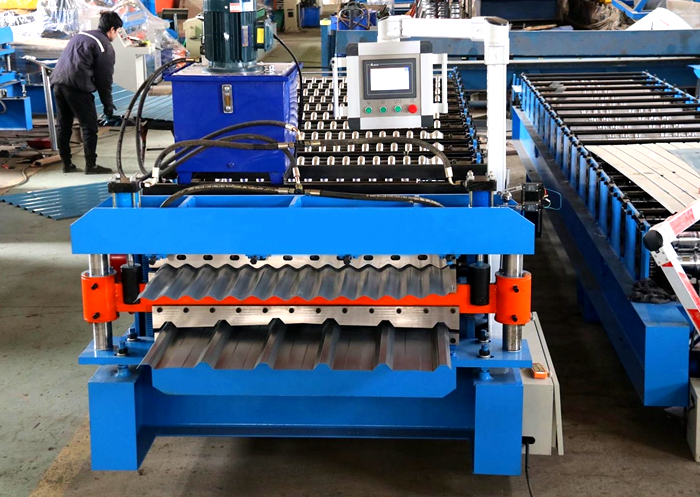

A corrugated iron curving machine is specifically designed to reshape flat sheets of corrugated iron into desired curves. This machinery employs advanced technology, often featuring hydraulic or mechanical systems, to apply the necessary pressure for bending the metal without compromising its integrity. The precision offered by these machines ensures that curves are consistent and tailored to specific project requirements.

The Role of Manufacturers

The efficiency and performance of a corrugated iron curving machine largely depend on the manufacturer. A reputable manufacturer will design and produce machines that not only meet industry standards but also incorporate user-friendly features that streamline the bending process. Additionally, manufacturers should prioritize producing machines that require minimal maintenance, thus reducing downtime for businesses.

When selecting a manufacturer, it is essential to assess their track record and expertise in the industry. A company with years of experience in manufacturing metalworking machinery is likely to understand the immediate and future needs of the construction sector. Furthermore, manufacturers that invest in research and development often produce innovative machinery that can adapt to emerging trends in building design.

Key Features to Consider

When exploring options for corrugated iron curving machines, several factors should be considered

1. Versatility The ability to curve different types of metals, not just corrugated iron, can be beneficial. A machine that can handle various thicknesses and materials increases its utility for diverse projects.

corrugated iron curving machine manufacturer

2. Precision and Accuracy Look for machines that guarantee high precision in bending. A well-calibrated machine minimizes waste and maximizes productivity.

3. User Experience Key features such as ease of operation, safety mechanisms, and maintenance support are vital. A user-friendly interface saves time during training and operation.

4. Build Quality Given the harsh conditions these machines often operate in, durability is paramount. Machines should be constructed from high-quality materials designed to withstand regular use.

5. Technical Support and Service Reliable after-sales support is crucial. Manufacturers should provide technical assistance and regular maintenance to ensure machines operate at optimal levels.

Benefits of Investing in a Corrugated Iron Curving Machine

Investing in a corrugated iron curving machine brings several advantages

- Cost Efficiency By producing curved sheets in-house, businesses can save on outsourcing costs and reduce lead times for projects.

- Enhanced Design Flexibility Contractors and architects can experiment with more fluid and dynamic designs, leading to innovative building projects that stand out.

- Sustainability Being able to utilize leftover material for curves contributes to reduced waste and promotes sustainable practices within the industry.

Conclusion

In conclusion, as the construction and roofing industries continue to evolve, the importance of specialized machinery, such as corrugated iron curving machines, cannot be overstated. Opting for a reputable manufacturer ensures access to high-quality, efficient machines that can aid in meeting modern architectural demands. By investing in such technology, businesses not only enhance their production capability but also contribute to the broader trend of innovation within the industry. Before making a purchase, it is essential for buyers to evaluate their options carefully and choose a manufacturer that aligns with their operational needs and standards.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025