Innovative Machine for Curving Corrugated Materials Efficiently and Accurately

The Importance of Corrugated Curving Machines in Modern Manufacturing

In today’s rapidly evolving manufacturing landscape, the efficiency and precision of production equipment play a pivotal role in determining the success of various industries. One such essential piece of equipment is the corrugated curving machine. This technology has transformed the way manufacturers handle corrugated materials, offering a range of benefits that enhance productivity and product quality.

What is a Corrugated Curving Machine?

A corrugated curving machine is a specialized device designed to shape corrugated sheets into various curve configurations. Corrugated materials, known for their durability and lightweight properties, are often used in packaging, construction, and even transportation. The ability to curve these sheets allows for innovative designs and applications, making the corrugated curving machine a must-have for manufacturers looking to innovate.

Key Features and Functionality

Modern corrugated curving machines boast advanced features that streamline the production process. Many units are equipped with digital controls that allow for precise adjustments, ensuring that the curvature meets exact specifications for each project. Automated feed systems enhance consistency, while integrated safety features safeguard operators during the manufacturing process.

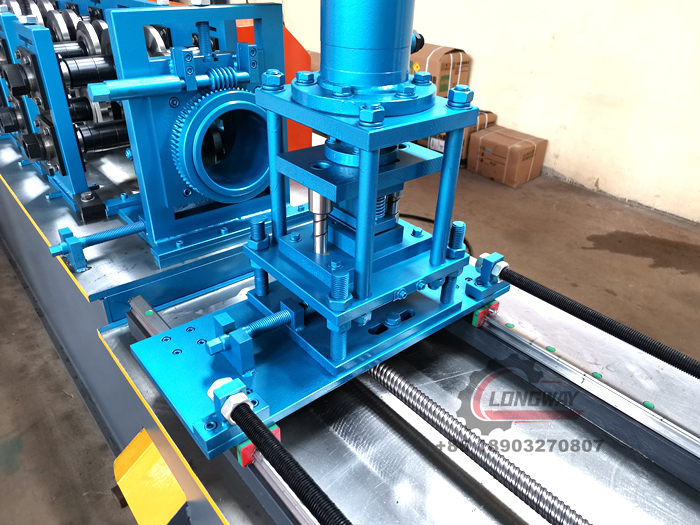

These machines typically work by feeding flat corrugated sheets through a series of rollers that incrementally bend the material to the desired angle. Depending on the model, manufacturers can achieve various radiuses of curvature, enabling greater versatility in design. Moreover, some advanced machines offer programmable settings that allow users to save frequently used curves, significantly reducing setup time for repetitive tasks.

Benefits of Corrugated Curving Machines

1. Increased Efficiency One of the primary advantages of utilizing a corrugated curving machine is the drastic improvement in operational efficiency. Automated processes reduce the time needed to curve materials manually, freeing up labor resources for other tasks. This increased throughput can lead to significant cost savings and improved delivery times.

corrugated curving machine

2. Enhanced Precision Traditional methods of curving corrugated materials often result in inconsistencies that can affect product quality. Corrugated curving machines provide a high degree of precision, ensuring that every piece produced meets stringent specifications. This consistency is crucial for industries that require high quality, such as aerospace and automotive sectors.

3. Innovative Design Capabilities With the ability to create complex curves, manufacturers can explore innovative designs that were previously unattainable with standard flat corrugated sheets. This capability allows businesses to differentiate their products in competitive markets, catering to specific customer needs and preferences.

4. Material Savings The advanced functionality of corrugated curving machines often leads to better material utilization. By minimizing waste during the curving process, manufacturers not only save on raw material costs but also contribute to a more sustainable production model.

5. Versatility Across Industries From packaging solutions to architectural elements, the applicability of curved corrugated materials spans various industries. Manufacturers can adapt the machine settings for diverse projects, which enhances their product offerings and attracts a broader customer base.

Future Trends

As technology continues to advance, the future of corrugated curving machines looks promising. Incorporation of AI and machine learning could lead to smarter machines that optimize production processes in real-time. Furthermore, advancements in materials science may yield new types of corrugated products that require different curving techniques, thereby driving innovation in machine design.

Conclusion

The corrugated curving machine stands as a vital tool in modern manufacturing, bridging the gap between technology and craftsmanship. Its ability to produce precise, innovative, and efficient curved corrugated materials positions manufacturers to meet the challenges of a competitive market. As industries continue to evolve, those that invest in advanced machinery like the corrugated curving machine will likely stay ahead, harnessing the potential for creativity and efficiency while addressing the demands of an ever-changing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025