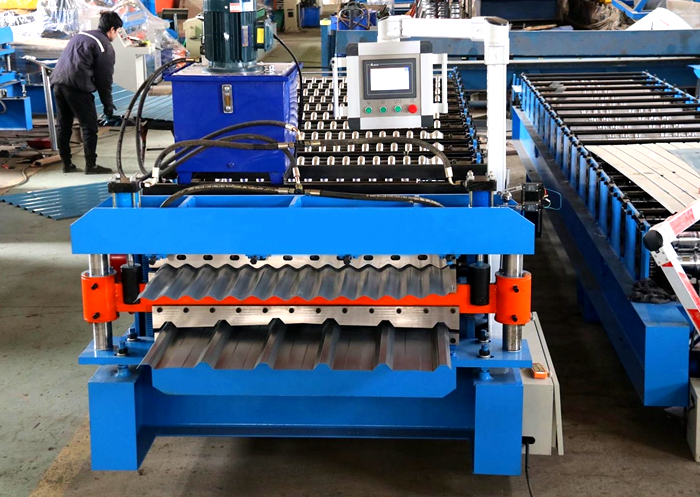

corrugated curving machine

The Corrugated Curving Machine Revolutionizing the Packaging Industry

In the contemporary manufacturing environment, efficiency and precision are paramount, especially in sectors like packaging where the demand for high-quality products is constant. One innovative solution that has emerged to meet these needs is the corrugated curving machine. This sophisticated device plays a crucial role in creating corrugated cardboard shapes that are essential for modern packaging applications.

What is a Corrugated Curving Machine?

A corrugated curving machine is a specialized piece of equipment designed to produce curved shapes from corrugated materials. These machines can bend, shape, and form corrugated cardboard into various configurations, which can be tailored to suit specific packaging requirements. This capability is increasingly significant as businesses strive to enhance their packaging designs while maintaining the structural integrity and protective qualities of the materials used.

How it Works

The operation of a corrugated curving machine is straightforward yet efficient. Typically, the machine features a feed mechanism that pulls sheets of corrugated cardboard into a shaping unit. The unit employs a combination of heat, pressure, and precise cutting tools to manipulate the material, achieving the desired curved shape. Advanced models can incorporate computer numerical control (CNC) technology, allowing for greater accuracy and repeatability in producing complex designs.

Applications of Corrugated Curving Machines

The applications of corrugated curving machines are vast and varied. They are predominantly used in the packaging industry for creating custom boxes, displays, and protective elements for shipping fragile products. The ability to produce curved forms enhances the aesthetic appeal of packaging, making products more attractive to consumers. Furthermore, curved packaging can improve the structural performance of products during transit, reducing the likelihood of damage.

corrugated curving machine

In industries such as electronics, glass, and furniture, where product safety is paramount, the use of specialized curved corrugated shapes ensures that items are secured and cushioned effectively. Additionally, the retail sector benefits from these machines by producing eye-catching display stands that can draw in customers and enhance the shopping experience.

Advantages of Corrugated Curving Machines

The introduction of corrugated curving machines in production lines offers numerous advantages. First and foremost is the potential for cost savings. By automating the shaping process, companies can reduce labor costs while increasing production speed. This efficiency allows for larger-scale production runs, which can significantly bolster a company's bottom line.

Moreover, these machines contribute to sustainability efforts. With the increasing focus on environmentally friendly packaging solutions, corrugated cardboard is a renewable resource that can be recycled. The ability to efficiently create curved designs means that manufacturers can use less material while still achieving robust packaging solutions, thereby minimizing waste.

In addition, the versatility of corrugated curving machines is worth highlighting. Manufacturers can produce a wide range of shapes and sizes to accommodate various products, making these machines invaluable in fulfilling diverse customer needs.

Conclusion

In conclusion, the corrugated curving machine represents a significant advancement in the packaging industry, offering unparalleled efficiency, versatility, and design capabilities. As businesses continue to prioritize economic sustainability and innovative packaging solutions, these machines will play a pivotal role in shaping the future of product packaging. With the ability to create unique forms that attract consumers while providing protection for products, corrugated curving machines are undoubtedly a driving force behind modern manufacturing practices. As technology evolves, we can anticipate even more sophisticated features and improvements in these machines, further enhancing their impact on the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025