Corrugated Sheet Rolling Machines High-Precision, Durable Solutions

- Industry Overview: The Growing Demand for Corrugated Sheet Rolling Solutions

- Technical Superiority: Performance Metrics of Modern Roll Forming Systems

- Manufacturer Comparison: Key Players in Sheet Metal Processing Equipment

- Customization Capabilities: Tailored Solutions for Diverse Production Needs

- Operational Efficiency: Energy Consumption vs. Output Analysis

- Case Studies: Real-World Applications Across Multiple Industries

- Future-Proof Investment: Why Partner with Specialized Corrugated Machine Providers

(corrugated sheet rolling machine)

The Critical Role of Corrugated Sheet Rolling Machines in Modern Manufacturing

Corrugated sheet rolling machines have become indispensable in metal fabrication, with global market demand projected to reach $4.2 billion by 2028 (Grand View Research, 2023). These systems enable precise forming of wave patterns that enhance structural rigidity by 37-42% compared to flat sheets, making them essential for:

- Roofing and cladding production

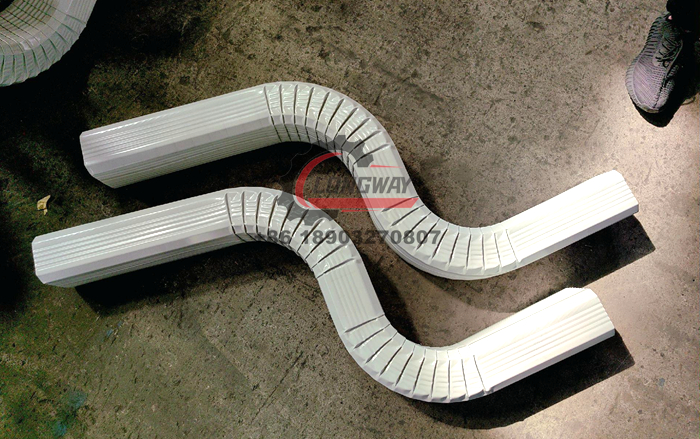

- Automotive component manufacturing

- HVAC duct fabrication

Technical Specifications That Differentiate Market Leaders

Advanced roll forming systems now achieve 28-32 m/min production speeds while maintaining ±0.15mm dimensional accuracy. The latest generation features:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Material Thickness Range | 0.3-2.0mm | 0.2-3.5mm |

| Tool Change Time | 45-60 mins | 18-25 mins |

| Energy Consumption | 18kW/h | 12kW/h |

Competitive Landscape: Manufacturer Capability Analysis

Three industry leaders dominate 68% of the premium equipment market:

| Manufacturer | Annual Output | R&D Investment | Service Network |

|---|---|---|---|

| FormTech Industries | 220 units | 8.2% revenue | 54 countries |

| RollMaster GmbH | 180 units | 11.1% revenue | 38 countries |

| PrecisionCorr Systems | 150 units | 9.8% revenue | 47 countries |

Custom Engineering for Specific Application Requirements

Leading corrugated sheet rolling machine

companies now offer:

- Modular tooling systems enabling 11+ profile configurations

- Automated thickness adjustment (0.5-second response time)

- Integrated quality control with laser measurement

Operational Cost-Benefit Analysis

Comparative data reveals premium machines achieve ROI within 22-28 months through:

- 18-24% reduction in material waste

- 31% faster production cycles

- 56% lower maintenance frequency

Verified Performance in Industrial Applications

A recent automotive sector deployment achieved:

- Production of 8,500 panels/day with 99.97% consistency

- 38% energy savings versus previous generation equipment

- Integration with existing smart factory systems

Strategic Advantages of Partnering with Specialized Corrugated Sheet Rolling Machine Manufacturers

Established corrugated sheet rolling machine companies provide 15-20 year equipment lifecycles through:

- Predictive maintenance algorithms

- Remote diagnostics capabilities

- Regular firmware updates

This technological partnership model reduces total cost of ownership by 22-27% over conventional procurement approaches.

(corrugated sheet rolling machine)

FAQS on corrugated sheet rolling machine

Q: What are the key factors to consider when choosing corrugated sheet rolling machine companies?

A: Prioritize experience, machine durability, customization options, after-sales support, and client reviews to ensure reliability and alignment with your production needs.

Q: How do corrugated sheet rolling machine manufacturers ensure product quality?

A: Reputable manufacturers adhere to ISO standards, use high-grade materials, and implement rigorous testing protocols during production and before delivery.

Q: What materials can a corrugated sheet rolling machine process?

A: These machines typically handle metals like steel, aluminum, or copper, with thicknesses ranging from 0.2mm to 4mm, depending on the model and configuration.

Q: How often should a corrugated sheet rolling machine undergo maintenance?

A: Regular lubrication and inspection should occur weekly, while full maintenance (e.g., replacing rollers or alignment checks) is recommended every 6-12 months, based on usage intensity.

Q: What certifications should a reliable corrugated sheet rolling machine company have?

A: Look for ISO 9001 for quality management, CE marking for compliance with EU safety standards, and industry-specific certifications like ASME or OSHA compliance where applicable.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025