Jun . 15, 2024 21:55

Back to list

Corrugated Metal Roller Companies

Corrugated Sheet Metal Roller Companies A Comprehensive Guide

Corrugated sheet metal roller companies play a crucial role in the manufacturing industry, providing essential equipment and services for the production of corrugated sheets. These rollers are used to shape and form metal sheets into various shapes and sizes, making them an integral part of many industrial processes. In this article, we will explore the key aspects of corrugated sheet metal roller companies, including their history, types of rollers, applications, and future trends.

History of Corrugated Sheet Metal Roller Companies

The use of corrugated sheet metal rollers can be traced back to the early 20th century, when they were first introduced as a means of shaping metal sheets more efficiently. Since then, these companies have continued to evolve and innovate, developing new technologies and techniques to meet the growing demands of the manufacturing industry. Today, corrugated sheet metal roller companies are an essential part of modern manufacturing processes, providing high-quality equipment and services to businesses around the world.

Types of Rollers Used by Corrugated Sheet Metal Roller Companies

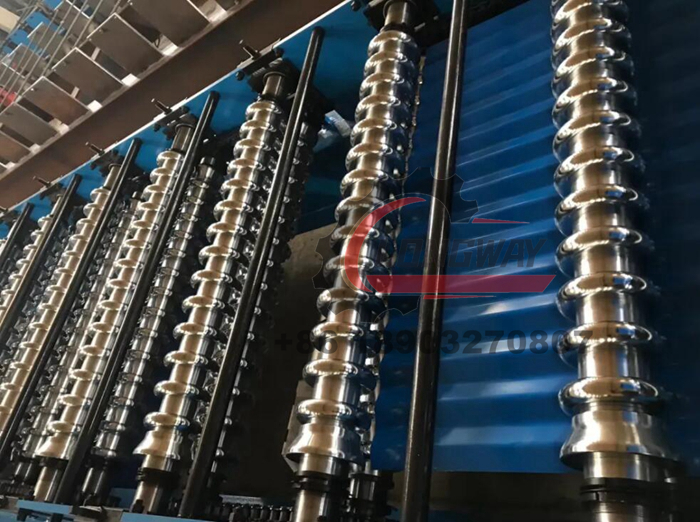

There are several types of rollers used by corrugated sheet metal roller companies, each with its own unique characteristics and applications. Some of the most common types include

1. Single-roller machines These machines use a single roller to shape the metal sheet. They are commonly used for simple shaping operations and are often found in small-scale manufacturing facilities.

2. Double-roller machines These machines use two rollers to shape the metal sheet. They are more versatile than single-roller machines and can handle a wider range of materials and shapes.

3. Multi-roller machines These machines use multiple rollers arranged in a series to shape the metal sheet. They are capable of producing complex shapes and are often used in high-volume production environments.

4. Profile rollers These rollers are designed to produce specific profiles or shapes in the metal sheet. They are commonly used in the production of roofing materials, gutters, and other building products.

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1 Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1 corrugated sheet metal roller companies. Construction Corrugated sheets are widely used in the construction industry for roofing, siding, and other building components.

2. Automotive The automotive industry uses corrugated sheets for a variety of purposes, including body panels, truck beds, and undercarriage components.

3. Aerospace Corrugated sheets are used in the aerospace industry for fuel tanks, air ducts, and other structural components.

4. Packaging Corrugated cardboard is a popular packaging material due to its strength, durability, and low cost.

5. Agriculture Corrugated sheets are used in the agriculture industry for livestock shelters, greenhouses, and other agricultural structures.

Future Trends in Corrugated Sheet Metal Roller Companies

As the manufacturing industry continues to evolve, corrugated sheet metal roller companies are facing new challenges and opportunities. Some of the key trends affecting these companies include

1. Automation The increasing use of automation technology in manufacturing processes is driving demand for more advanced corrugated sheet metal roller equipment.

2. Sustainability There is growing interest in sustainable manufacturing practices, which could lead to increased demand for eco-friendly corrugated sheet metal roller equipment and materials.

3. Digitalization The integration of digital technologies, such as robotics and advanced sensors, into corrugated sheet metal roller equipment is improving efficiency and accuracy in manufacturing processes.

4. Customization Customers are increasingly demanding customized solutions, which could drive demand for specialized corrugated sheet metal roller equipment and services.

corrugated sheet metal roller companies. Construction Corrugated sheets are widely used in the construction industry for roofing, siding, and other building components.

2. Automotive The automotive industry uses corrugated sheets for a variety of purposes, including body panels, truck beds, and undercarriage components.

3. Aerospace Corrugated sheets are used in the aerospace industry for fuel tanks, air ducts, and other structural components.

4. Packaging Corrugated cardboard is a popular packaging material due to its strength, durability, and low cost.

5. Agriculture Corrugated sheets are used in the agriculture industry for livestock shelters, greenhouses, and other agricultural structures.

Future Trends in Corrugated Sheet Metal Roller Companies

As the manufacturing industry continues to evolve, corrugated sheet metal roller companies are facing new challenges and opportunities. Some of the key trends affecting these companies include

1. Automation The increasing use of automation technology in manufacturing processes is driving demand for more advanced corrugated sheet metal roller equipment.

2. Sustainability There is growing interest in sustainable manufacturing practices, which could lead to increased demand for eco-friendly corrugated sheet metal roller equipment and materials.

3. Digitalization The integration of digital technologies, such as robotics and advanced sensors, into corrugated sheet metal roller equipment is improving efficiency and accuracy in manufacturing processes.

4. Customization Customers are increasingly demanding customized solutions, which could drive demand for specialized corrugated sheet metal roller equipment and services.

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1

Applications of Corrugated Sheet Metal Roller Companies

Corrugated sheet metal roller companies provide equipment and services for a wide range of industries, including

1 corrugated sheet metal roller companies. Construction Corrugated sheets are widely used in the construction industry for roofing, siding, and other building components.

2. Automotive The automotive industry uses corrugated sheets for a variety of purposes, including body panels, truck beds, and undercarriage components.

3. Aerospace Corrugated sheets are used in the aerospace industry for fuel tanks, air ducts, and other structural components.

4. Packaging Corrugated cardboard is a popular packaging material due to its strength, durability, and low cost.

5. Agriculture Corrugated sheets are used in the agriculture industry for livestock shelters, greenhouses, and other agricultural structures.

Future Trends in Corrugated Sheet Metal Roller Companies

As the manufacturing industry continues to evolve, corrugated sheet metal roller companies are facing new challenges and opportunities. Some of the key trends affecting these companies include

1. Automation The increasing use of automation technology in manufacturing processes is driving demand for more advanced corrugated sheet metal roller equipment.

2. Sustainability There is growing interest in sustainable manufacturing practices, which could lead to increased demand for eco-friendly corrugated sheet metal roller equipment and materials.

3. Digitalization The integration of digital technologies, such as robotics and advanced sensors, into corrugated sheet metal roller equipment is improving efficiency and accuracy in manufacturing processes.

4. Customization Customers are increasingly demanding customized solutions, which could drive demand for specialized corrugated sheet metal roller equipment and services.

corrugated sheet metal roller companies. Construction Corrugated sheets are widely used in the construction industry for roofing, siding, and other building components.

2. Automotive The automotive industry uses corrugated sheets for a variety of purposes, including body panels, truck beds, and undercarriage components.

3. Aerospace Corrugated sheets are used in the aerospace industry for fuel tanks, air ducts, and other structural components.

4. Packaging Corrugated cardboard is a popular packaging material due to its strength, durability, and low cost.

5. Agriculture Corrugated sheets are used in the agriculture industry for livestock shelters, greenhouses, and other agricultural structures.

Future Trends in Corrugated Sheet Metal Roller Companies

As the manufacturing industry continues to evolve, corrugated sheet metal roller companies are facing new challenges and opportunities. Some of the key trends affecting these companies include

1. Automation The increasing use of automation technology in manufacturing processes is driving demand for more advanced corrugated sheet metal roller equipment.

2. Sustainability There is growing interest in sustainable manufacturing practices, which could lead to increased demand for eco-friendly corrugated sheet metal roller equipment and materials.

3. Digitalization The integration of digital technologies, such as robotics and advanced sensors, into corrugated sheet metal roller equipment is improving efficiency and accuracy in manufacturing processes.

4. Customization Customers are increasingly demanding customized solutions, which could drive demand for specialized corrugated sheet metal roller equipment and services. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products