Jun . 28, 2024 06:10

Back to list

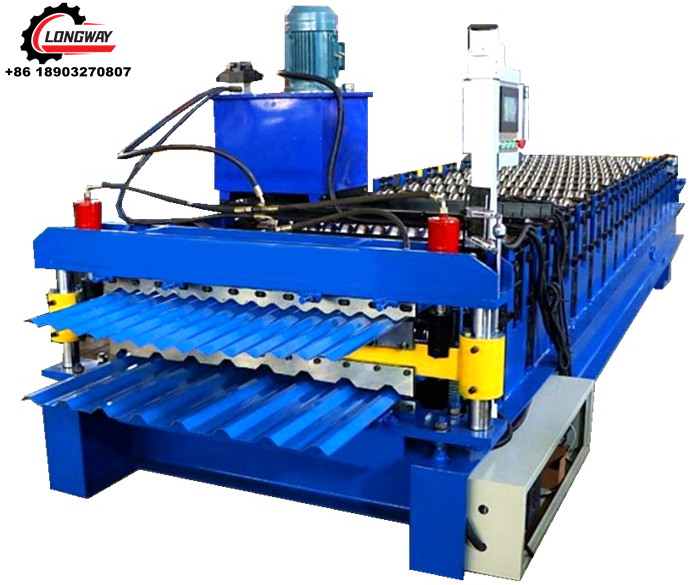

Corrugated Iron Roofing Sheet Manufacturing Machine Affordable Prices from Leading Suppliers

Understanding Corrugated Iron Roofing Sheet Making Machines Manufacturers and Pricing Factors

Corrugated iron roofing sheets have long been a staple in the construction industry due to their durability, affordability, and ease of installation. The production of these sheets is largely dependent on specialized machinery, the corrugated iron roofing sheet making machine. This article delves into the world of these machines, focusing on manufacturers, pricing, and the factors that influence their cost.

A corrugated iron roofing sheet making machine is a sophisticated piece of equipment designed to transform raw metal into sturdy, wave-patterned sheets suitable for roofing and cladding purposes. Leading manufacturers in this field include names like China's Baoding Roll Forming Machinery Co., Ltd., Italy's Pama Srl, and India's Jayant Impex Pvt Ltd. These companies, among others, are renowned for their high-quality machines, advanced technology, and excellent customer service.

The price of a corrugated iron roofing sheet making machine varies greatly depending on several factors. Firstly, the capacity and efficiency of the machine play a significant role. A larger, more automated machine capable of producing a higher volume of sheets at a faster rate will typically command a higher price than a smaller, manual model. For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000

For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 corrugated iron roofing sheet making machine price manufacturer.

Secondly, the technology incorporated in the machine affects the cost. Advanced features such as computerized control systems, precision rolling, and automated cutting can increase the initial investment but also enhance productivity and reduce labor costs in the long run. The choice between a hydraulic, mechanical, or electrical drive system can also impact the price.

Thirdly, customization requirements can sway the pricing. Each manufacturer offers a standard set of specifications, but customizations like different sheet profiles, material compatibility, or additional accessories can lead to a tailored solution but also add to the overall cost.

Lastly, the brand reputation and after-sales service provided by the manufacturer contribute to the price. Established brands often charge a premium for their reliability and warranty coverage, which can be a significant factor for businesses looking for long-term investment security.

In conclusion, when considering the purchase of a corrugated iron roofing sheet making machine, it's crucial to weigh the initial investment against the expected return on investment. Factors such as production capacity, technology, customization, and manufacturer support should all be taken into account. While the price may seem steep, the efficiency and productivity gains these machines offer make them a worthwhile investment for businesses involved in the roofing and construction sector.

corrugated iron roofing sheet making machine price manufacturer.

Secondly, the technology incorporated in the machine affects the cost. Advanced features such as computerized control systems, precision rolling, and automated cutting can increase the initial investment but also enhance productivity and reduce labor costs in the long run. The choice between a hydraulic, mechanical, or electrical drive system can also impact the price.

Thirdly, customization requirements can sway the pricing. Each manufacturer offers a standard set of specifications, but customizations like different sheet profiles, material compatibility, or additional accessories can lead to a tailored solution but also add to the overall cost.

Lastly, the brand reputation and after-sales service provided by the manufacturer contribute to the price. Established brands often charge a premium for their reliability and warranty coverage, which can be a significant factor for businesses looking for long-term investment security.

In conclusion, when considering the purchase of a corrugated iron roofing sheet making machine, it's crucial to weigh the initial investment against the expected return on investment. Factors such as production capacity, technology, customization, and manufacturer support should all be taken into account. While the price may seem steep, the efficiency and productivity gains these machines offer make them a worthwhile investment for businesses involved in the roofing and construction sector.

For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000

For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 For instance, a fully automatic machine with a high production capacity could range from $50,000 to $150,000, while a semi-automatic or manual model might be priced between $10,000 to $30,000 corrugated iron roofing sheet making machine price manufacturer.

Secondly, the technology incorporated in the machine affects the cost. Advanced features such as computerized control systems, precision rolling, and automated cutting can increase the initial investment but also enhance productivity and reduce labor costs in the long run. The choice between a hydraulic, mechanical, or electrical drive system can also impact the price.

Thirdly, customization requirements can sway the pricing. Each manufacturer offers a standard set of specifications, but customizations like different sheet profiles, material compatibility, or additional accessories can lead to a tailored solution but also add to the overall cost.

Lastly, the brand reputation and after-sales service provided by the manufacturer contribute to the price. Established brands often charge a premium for their reliability and warranty coverage, which can be a significant factor for businesses looking for long-term investment security.

In conclusion, when considering the purchase of a corrugated iron roofing sheet making machine, it's crucial to weigh the initial investment against the expected return on investment. Factors such as production capacity, technology, customization, and manufacturer support should all be taken into account. While the price may seem steep, the efficiency and productivity gains these machines offer make them a worthwhile investment for businesses involved in the roofing and construction sector.

corrugated iron roofing sheet making machine price manufacturer.

Secondly, the technology incorporated in the machine affects the cost. Advanced features such as computerized control systems, precision rolling, and automated cutting can increase the initial investment but also enhance productivity and reduce labor costs in the long run. The choice between a hydraulic, mechanical, or electrical drive system can also impact the price.

Thirdly, customization requirements can sway the pricing. Each manufacturer offers a standard set of specifications, but customizations like different sheet profiles, material compatibility, or additional accessories can lead to a tailored solution but also add to the overall cost.

Lastly, the brand reputation and after-sales service provided by the manufacturer contribute to the price. Established brands often charge a premium for their reliability and warranty coverage, which can be a significant factor for businesses looking for long-term investment security.

In conclusion, when considering the purchase of a corrugated iron roofing sheet making machine, it's crucial to weigh the initial investment against the expected return on investment. Factors such as production capacity, technology, customization, and manufacturer support should all be taken into account. While the price may seem steep, the efficiency and productivity gains these machines offer make them a worthwhile investment for businesses involved in the roofing and construction sector. Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products