Corrugated Roof Sheet Production Line with Roll Forming Technology for Efficient Manufacturing

Corrugated Roof Sheet Roll Forming Machine An Overview

In modern construction, the choice of materials and methods plays a vital role in determining the durability and efficiency of a building. Among various materials, corrugated roofing sheets have become increasingly popular due to their lightweight, strength, and resistance to environmental factors. Key to the production of these sheets is the corrugated roof sheet roll forming machine, an innovative piece of equipment that has revolutionized the manufacturing process.

Understanding Corrugated Roof Sheets

Corrugated roof sheets are made from different materials such as metal, plastic, and fiberglass. They are characterized by their wavy pattern, which provides structural strength and enhances water drainage, making them ideal for roofs in various climates. These sheets are widely used in industrial, commercial, and even residential buildings, offering an effective solution for roofing needs.

The demand for corrugated sheets has grown over the years, thanks to their durability and aesthetic appeal. This surge in demand has necessitated efficient manufacturing processes, which is where the corrugated roof sheet roll forming machine comes into play.

The Role of Roll Forming Machines

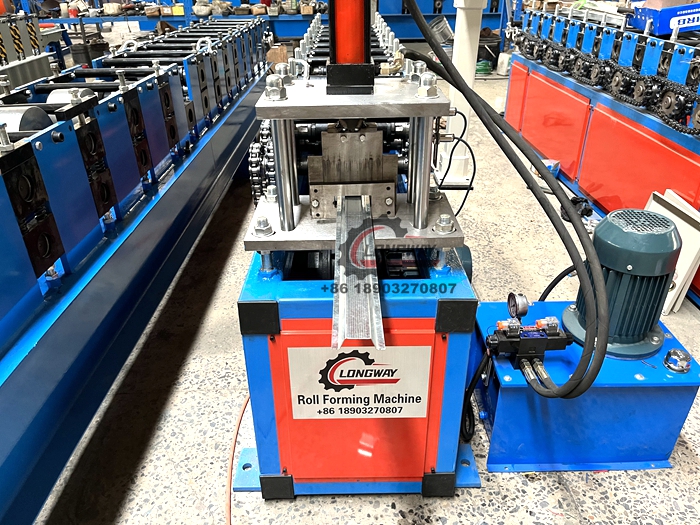

A corrugated roof sheet roll forming machine is engineered to produce continuous lengths of corrugated roofing panels from flat metal sheets. The process begins with coiling, where a flat sheet of material is fed into the machine. As the sheet passes through a series of rollers, it is progressively shaped into the desired corrugated profile. This gradual bending process is what gives the roofing sheets their characteristic strength and rigidity.

One of the main advantages of using a roll forming machine is its efficiency. These machines have a high production rate, allowing manufacturers to produce large quantities of roofing sheets in a short period. Furthermore, they ensure uniformity in the shape and size of the sheets, which is critical for installation and structural integrity.

Key Features of Roll Forming Machines

Modern corrugated roof sheet roll forming machines come equipped with advanced technology that enhances their performance

. Some key features include1. Automatic Control Systems Many machines have automated controls that enable precise adjustment of the roll forming process, ensuring consistent quality.

2. High-Quality Rollers Durable and precisely machined rollers are essential to produce high-quality sheets. They ensure that the sheets maintain their profile over time without warping.

corraugated roof sheet roll forming machine

3. Variable Speed Options The ability to adjust the speed allows manufacturers to optimize production according to their requirements without compromising quality.

4. Integrated Cutting Systems Most machines include automated cutting mechanisms that trim the finished sheets to the desired length, reducing labor costs and production time.

5. Versatility Some corrugated roof sheet roll forming machines can produce different profiles by merely changing the roller setup, making them an investment for manufacturers looking to diversify their product offerings.

Benefits of Using Corrugated Roof Sheet Roll Forming Machines

Using roll forming machines for producing corrugated roof sheets offers several benefits

- Cost Efficiency The automation and speed of production help reduce labor costs and material waste, significantly lowering the overall manufacturing expenses.

- Customization Manufacturers can easily customize sheet profiles and dimensions, catering to specific client needs or project requirements.

- Enhanced Durability The roll forming process improves the physical properties of metal, resulting in stronger and more resilient roofing sheets.

- Eco-Friendliness Many manufacturers are now utilizing recycled materials in the production of corrugated sheets, contributing to sustainable building practices.

Conclusion

In conclusion, the corrugated roof sheet roll forming machine serves as a crucial asset in the manufacturing of roofing materials. Its efficiency, versatility, and advanced technology significantly contribute to meeting the growing demand for quality roofing solutions. As the construction industry continues to evolve, investing in such machines will likely play a pivotal role in ensuring that manufacturers can keep pace with market requirements while delivering superior products. The future of construction is bright, with innovations like roll forming machines leading the way!

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025